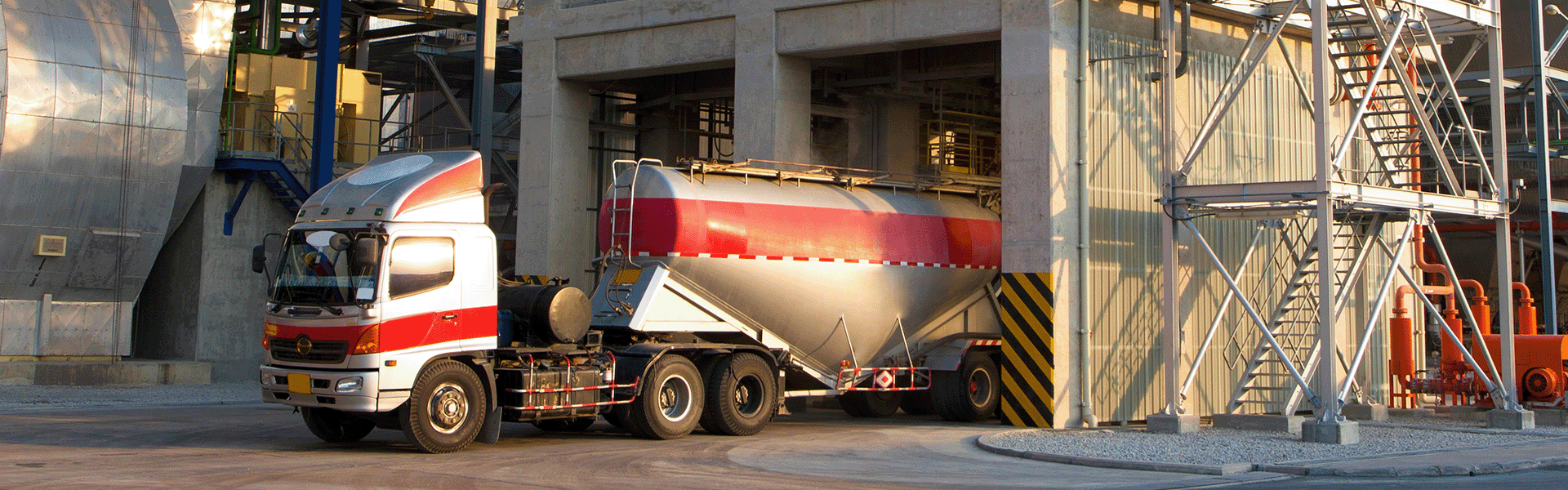

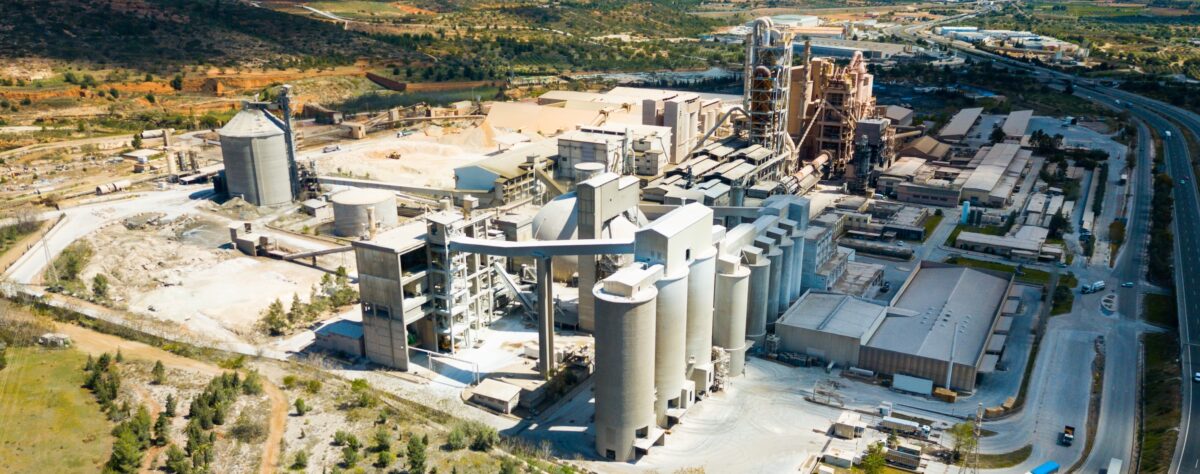

Bulk and bag material loading is a complex task that requires several systems to work together seamlessly to ensure correct loading: the right truck needs to load the right material in the right amount. This is crucial, as even slight underloading accumulates rapidly over the long term, creating costly inefficiencies, while overloading a truck may have even legal consequences.

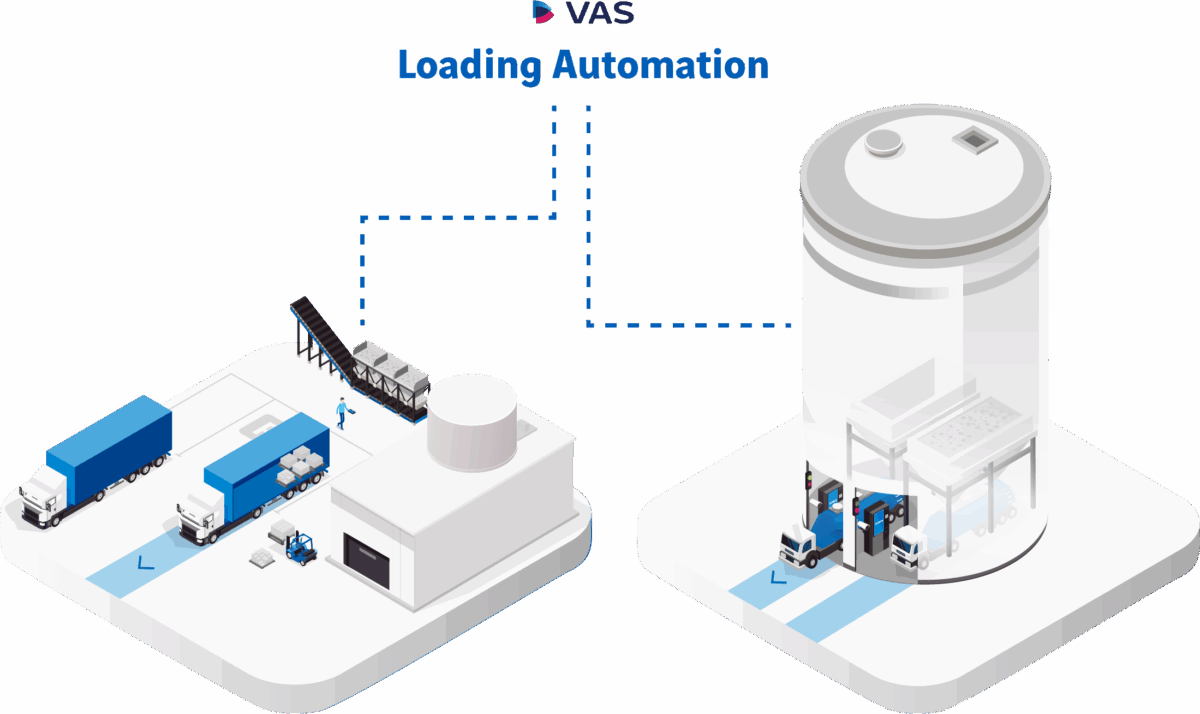

Furthermore, loading is often still done manually and therefore slow, inefficent and error-prone. VAS Loading automation changes that by automating and optimizing your loading processes – whether via silo, wheel loader or fork lift.