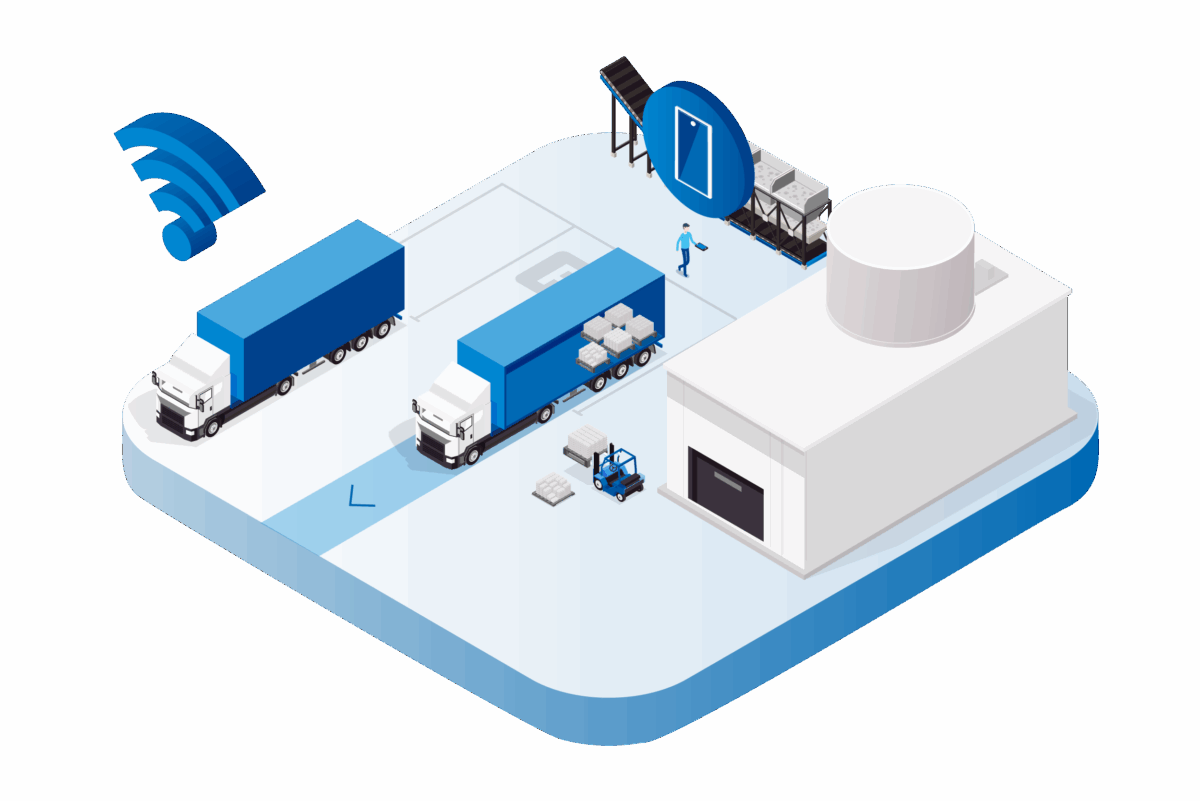

Forklifts are an important and versatile tool in bulk material loading as they enable the loading of whole pallets, significantly improving the throughput time. But – like all manual processes – forklift operation is prone to inefficiencies and errors, if not integrated into a central Yard Management System like VAS.

VAS forklift integration optimizes your loading process and ensures less downtime and better overview over your pallet inventory.