Axians IAS and Tübingen-based Optocycle GmbH have agreed on a strategic partnership to fully integrate Optocycle’s innovative AI-based material recognition and analysis into the market-leading Axians VAS plant logistics solution. This powerful end-to-end solution enables building material manufacturers and recycling companies to handle their inbound and outbound delivery processes even more precisely, safely and efficiently.

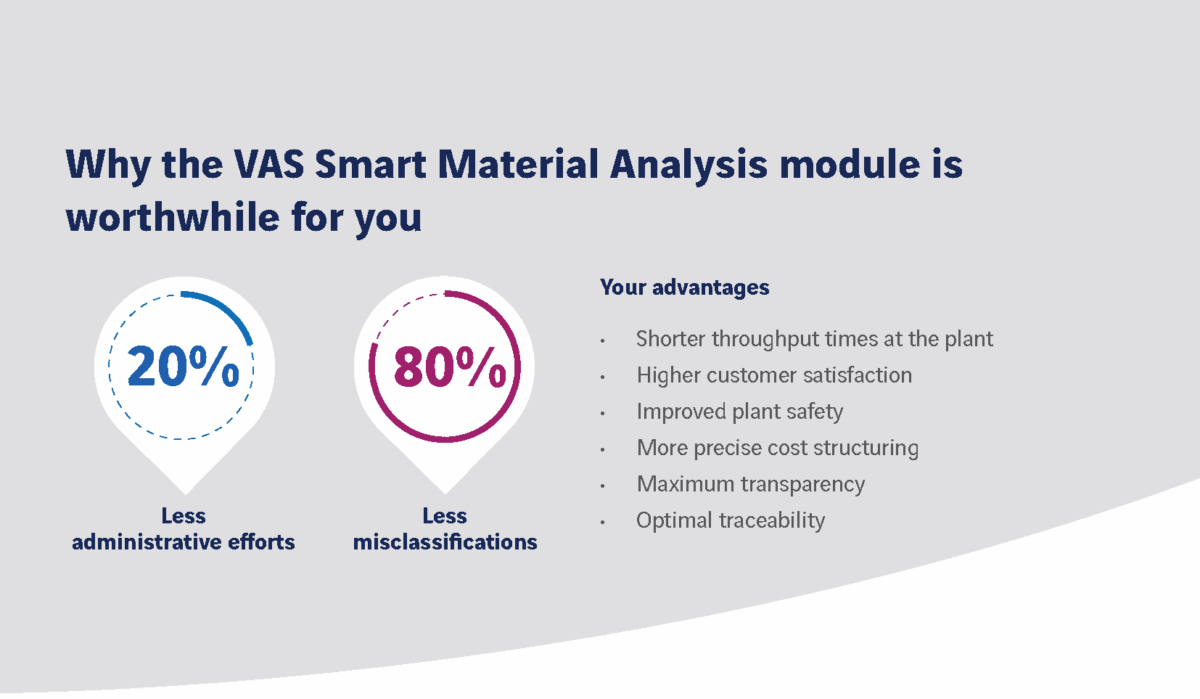

For both traditional building material manufacturers and the operators of landfill and recycling facilities, a more precise allocation of delivered materials and the avoidance of incorrect loads during delivery creates direct added value – while optimizing and simplifying existing processes.