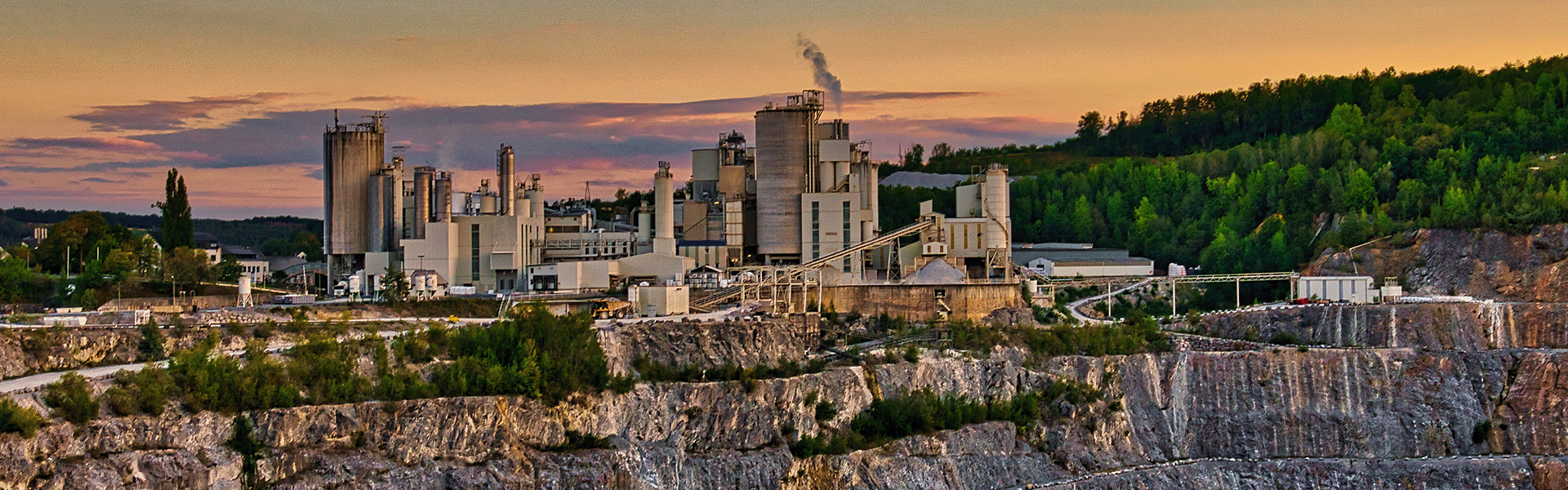

SCHAEFER KALK GmbH & Co. KG is one of the leading manufacturers of lime and calcium carbonate products in Europe. With over ten locations worldwide and a wide range of customers – from self-collectors to international industrial customers – logistics is a key success factor.

The challenge

Designing complex logistics efficiently

Especially at the main Hahnstätten plant with a couple of limestone quarries and the Steeden plant, there was room for improvements:

Manual processes, high communication costs with drivers, subcontractors and plant staff as well as bottlenecks during loading made handling more difficult. The aim of the VAS introduction was to significantly increase the transparency and efficiency of the processes, minimize sources of error and provide digitized and automated plant logistics – from pre-planning to entry and delivery note creation.

The solution: VAS Yard Management from Axians IAS

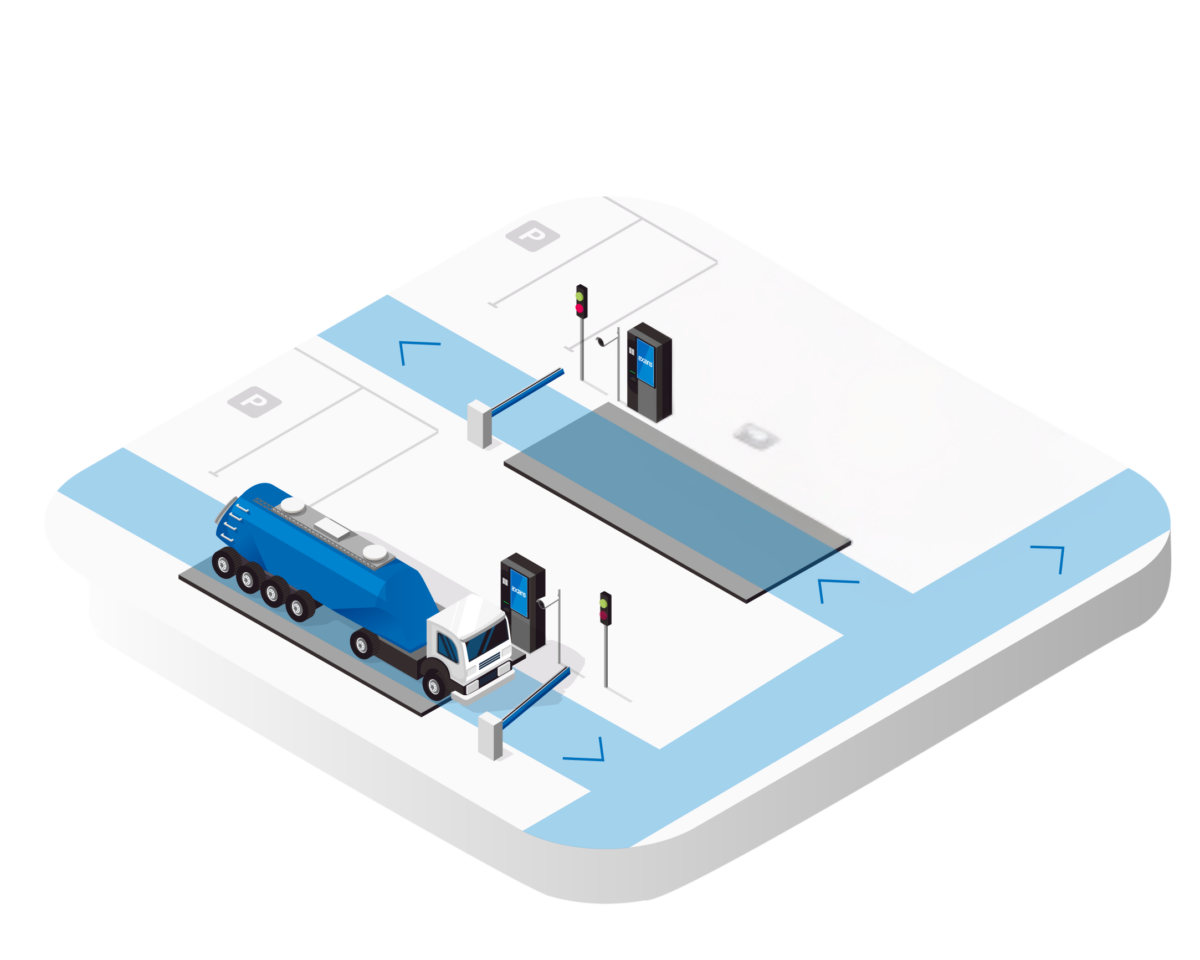

With the modular plant logistics solution VAS Yard Management a system was introduced that is specially tailored to the requirements of bulk goods logistics. VAS integrates seamlessly into the existing IT and control landscape at SCHAEFER KALK via its open interfaces and communicates with Microsoft Dynamics NAV, SCHAEFER KALK’s ERP system, as well as with weighing technology, access control and process control systems.

All logistics-relevant processes – from pre-planning, check-in, loading and check-out to document creation – now run digitally and automatically in a central software environment.

Central pre-planning as a digital basis for smooth plant processes

In addition to plant logistics, a central, digital order entry and planning system from Axians IAS was also introduced at SCHAEFER KALK. Customers can now digitally create orders and deliveries based on their contracts and make them directly available to both SCHAEFER KALK and the hauliers, that can be commissioned by the customer as part of transport planning. The truck drivers receive the delivery instructions by e-mail and can easily check in at the plant entrance using the QR code provided in the e-mail.

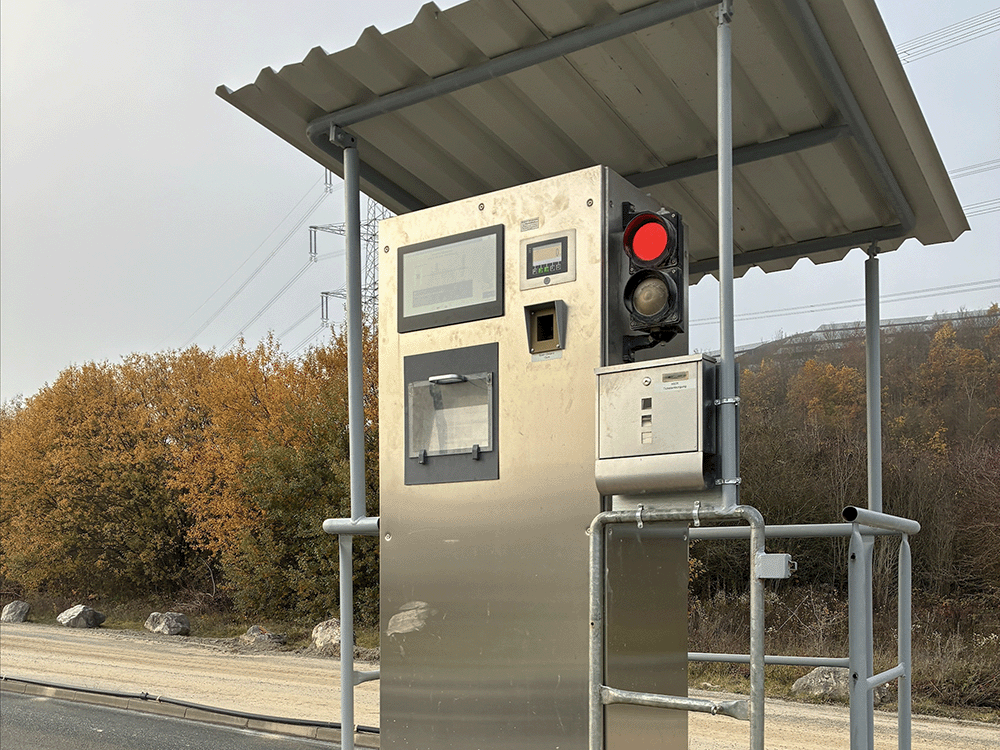

Automated plant entrance and exit: self-service with QR code

One highlight of the VAS plant logistics solution is the fully digitized handling of trucks at the entrance and exit:

- Check-in via self-service terminal: The truck drivers identify themselves by scanning the QR code provided with the delivery instructions (this is generated in the central VAS tool for order pre-planning) or by entering the order number at the terminal. All relevant delivery data is already available to the system – the driver receives clear instructions for loading.

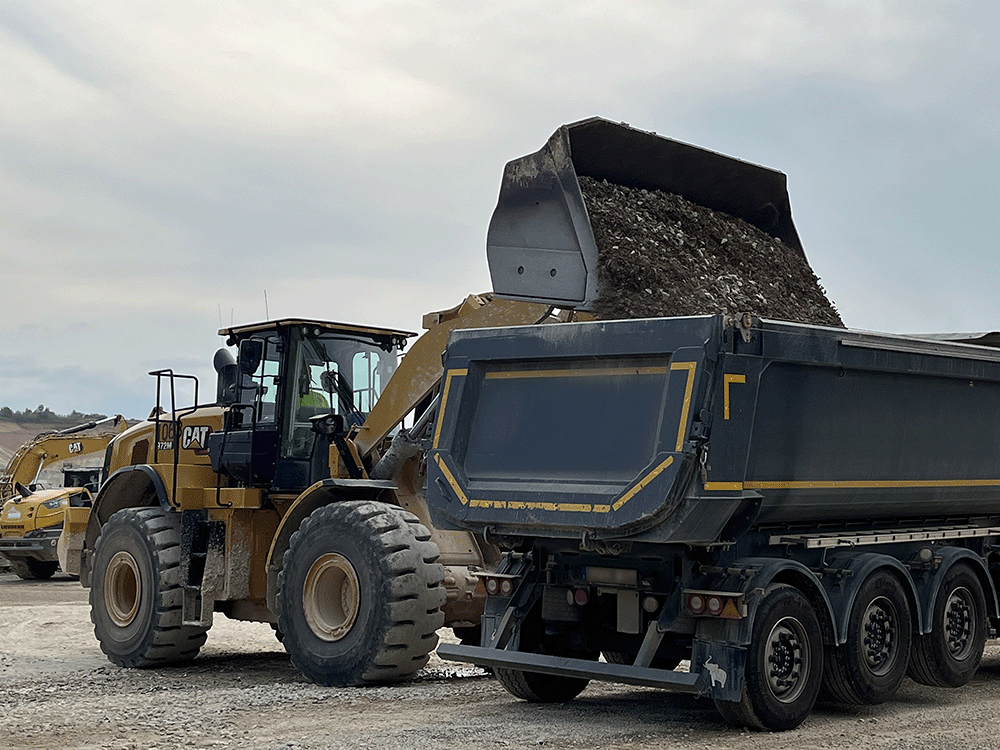

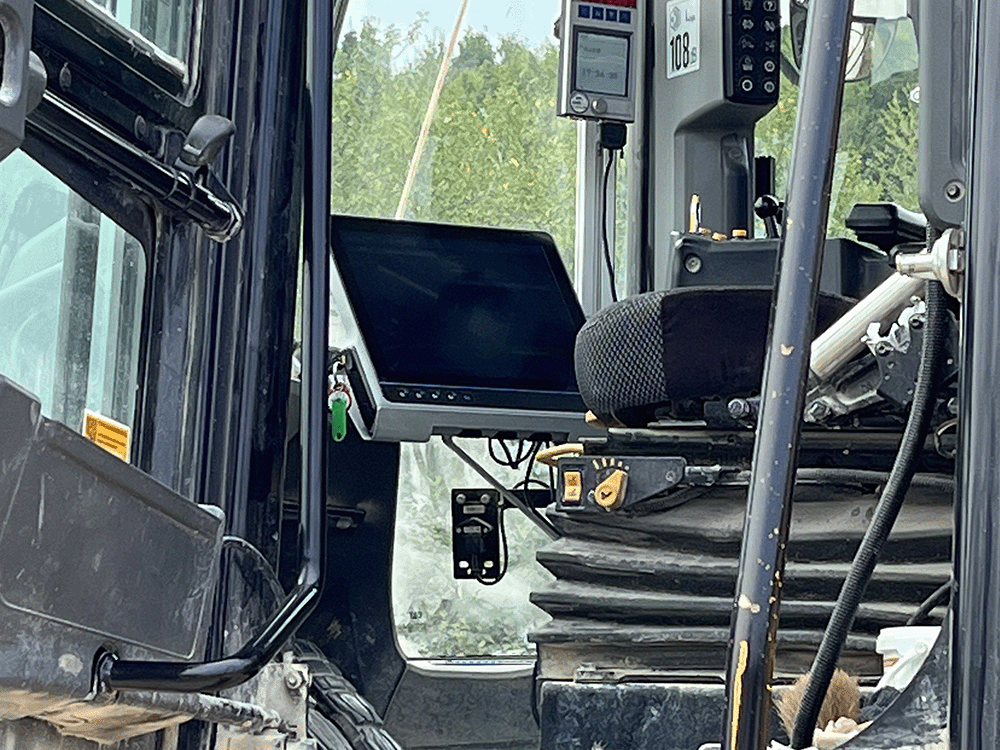

- Digitized loading process: The VAS system shows the wheel loader operator the delivery information directly on a terminal in the vehicle. The online connected wheel loader scales measure the currently loaded weight and automatically transmit the data to the VAS system.

- Check-out & delivery note creation: After loading, the driver scans the QR code of his loading bill at the VAS exit terminal. Once the exit weighing is complete, the delivery bill, including the weighing data, is automatically generated and made available to the driver – without any manual intermediate steps.

Subcontractors who carry out deliveries for small customers and self-collectors at SCHAEFER KALK with wheel loaders are also integrated into this fully automated solution – in some cases including online connection of the wheel loader scales to the VAS.

In the past, the wheel loader driver sometimes had to guess what was to be loaded and handle paper delivery notes- today, the VAS system controls the process precisely and digitally. Errors and waiting times are a thing of the past.

Head of IT Department, SCHAEFER KALK

Project implementation: step by step to the goal

The VAS implementation took place in several phases – closely supported by the experts of Axians IAS. Following a comprehensive analysis of the current workflows and the definition of the target processes, the yard management system was implemented step by step: Axians IAS designed a company-wide VAS template specially tailored to the requirements of SCHAEFER KALK to ensure that the software was optimally adapted to the customer’s logistics processes and to facilitate the roll-out in other plants.

As part of the VAS implementation, Axians IAS also provided hardware components such as self-service terminals at the entrance and exit as well as wheel loader terminals. In addition, existing weighing systems and webcams were connected online to the VAS system in order to record and identify the trucks and measure the loading weight in real time. In addition, the structure and appearance of the menu at the self-service terminals were adapted to the specific requirements of SCHAEFER KALK.

During the system changeover, the employees of SCHAEFER KALK were supported by Axians IAS with training and a change management program to ensure a smooth transition to the new, digitized processes.

Following the go-live of the VAS solution at the Merschelbruch and Steeden plants, Axians IAS is now assisting SCHAEFER KALK with support and ongoing optimizations.

Significant process improvements

By introducing the digital VAS Yard Management solution and the order entry and planning system from Axians IAS, SCHAEFER KALK was able to significantly improve the efficiency of its plant logistics processes:

- Up to 20 % faster truck dispatch thanks to automated processes

- Reduced manual effort for staff and drivers

- Greater process reliability thanks to automated documentation and data transfer

- Real-time transparency for logistics control and traceability

- Optimized production planning through digital pre-registration and order planning

- Integration of subcontractors into the digitized processes

- Scalable, hardware-independent platform for further automation steps

With the VAS solutions from Axians IAS, we have implemented a central lever for the digitalization of our logistics processes. The close integration into our IT landscape and the high level of process consistency make VAS the ideal platform for our future automation projects.

Head of IT Department, SCHAEFER KALK

Automation of further plants and logistics processes planned with VAS

Following the successful introduction of VAS in two plants, it is now being extended to other logistics processes and locations, covering the following use cases:

- Directly controlled silo loading

- Railway loading

- Complete support for bag loading

(incl. terminals on forklift trucks) - Online connection of the WINLIMS laboratory system to VAS

Thanks to the flexible system architecture, existing templates and experiences can be adopted easily and efficiently – for rapid scaling and consistent digitalization of the entire plant logistics.

About SCHAEFER KALK

Lime at its best

With over 700 employees, SCHAEFER KALK is one of the leading suppliers of high-quality lime products and precipitated calcium carbonates (PCC). Based on one of the purest limestone deposits in Europe, the company supplies customized solutions for a wide range of industries – from construction and chemicals to pharmaceuticals and the food industry.

Do you have any questions?

Contact our team of experts

Phone: +49 731 1551-0

Mail: info@axians-ias.com

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information