In many sand, gravel and bulk goods plants, the processes involved in storage and loading are still predominantly manual. A lack of transparency and inaccurate inventory data lead to waiting times, inefficient stock transfers and unnecessary production orders.

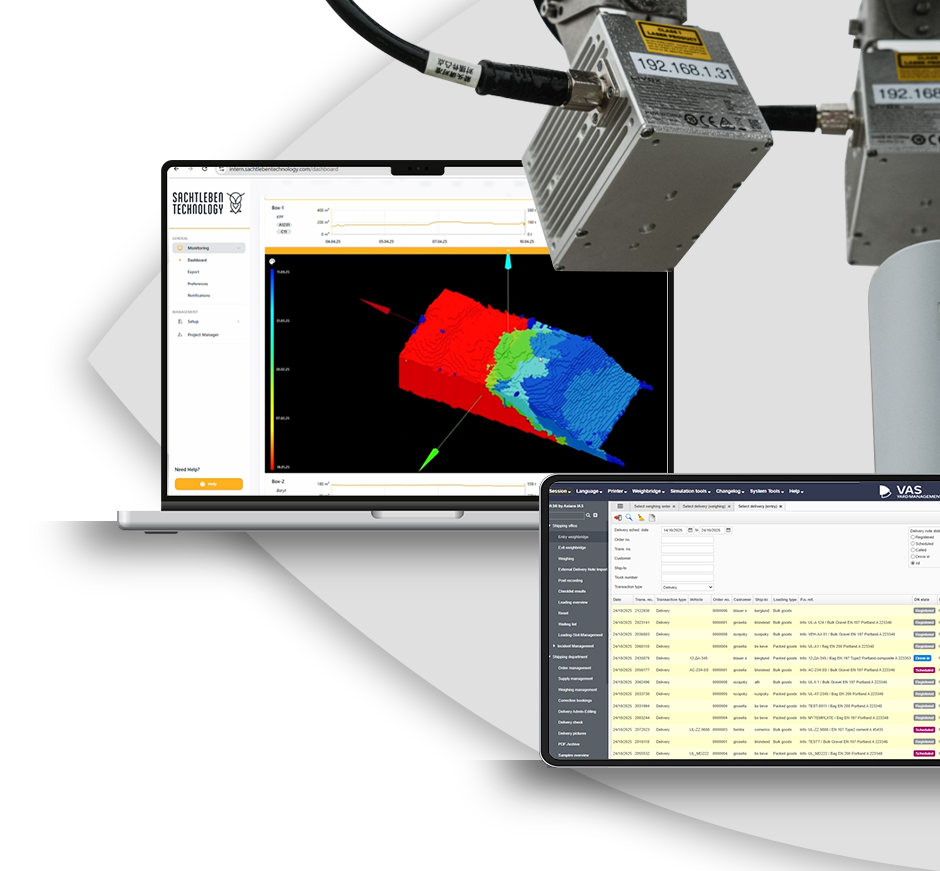

Two established providers – Sachtleben Technology, a specialist in sensor-based material detection, and Axians IAS, a provider of digital plant logistics solutions – have now announced a strategic partnership to address this challenge with an integrated solution that makes real-time data on material availability visible in the automated control of loading processes.