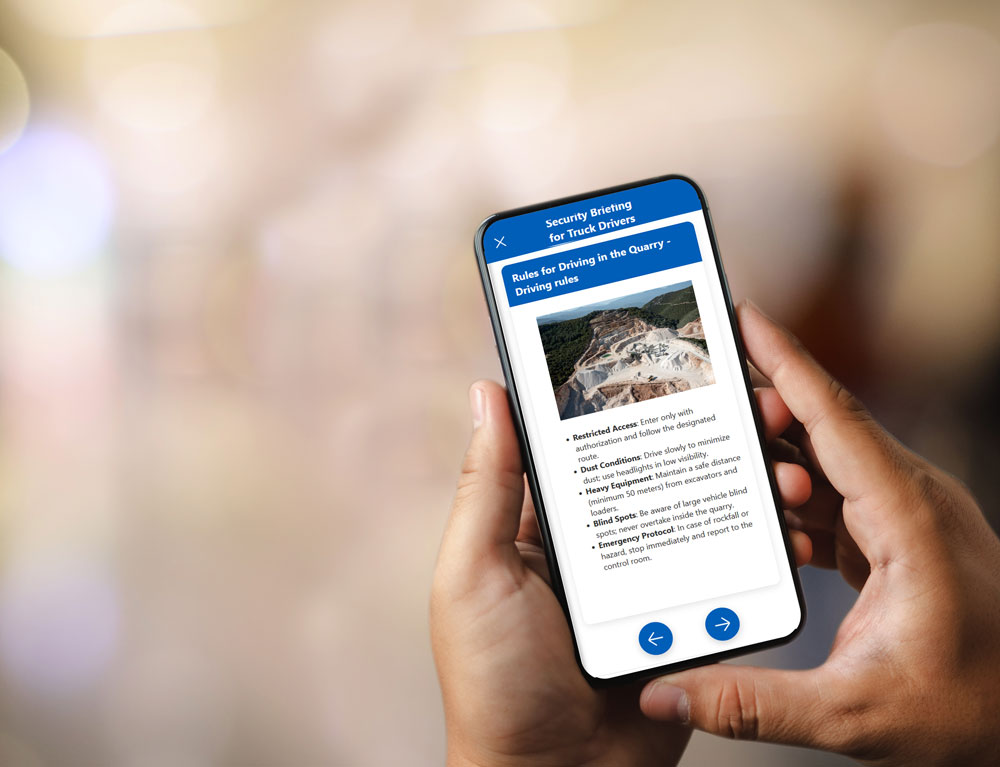

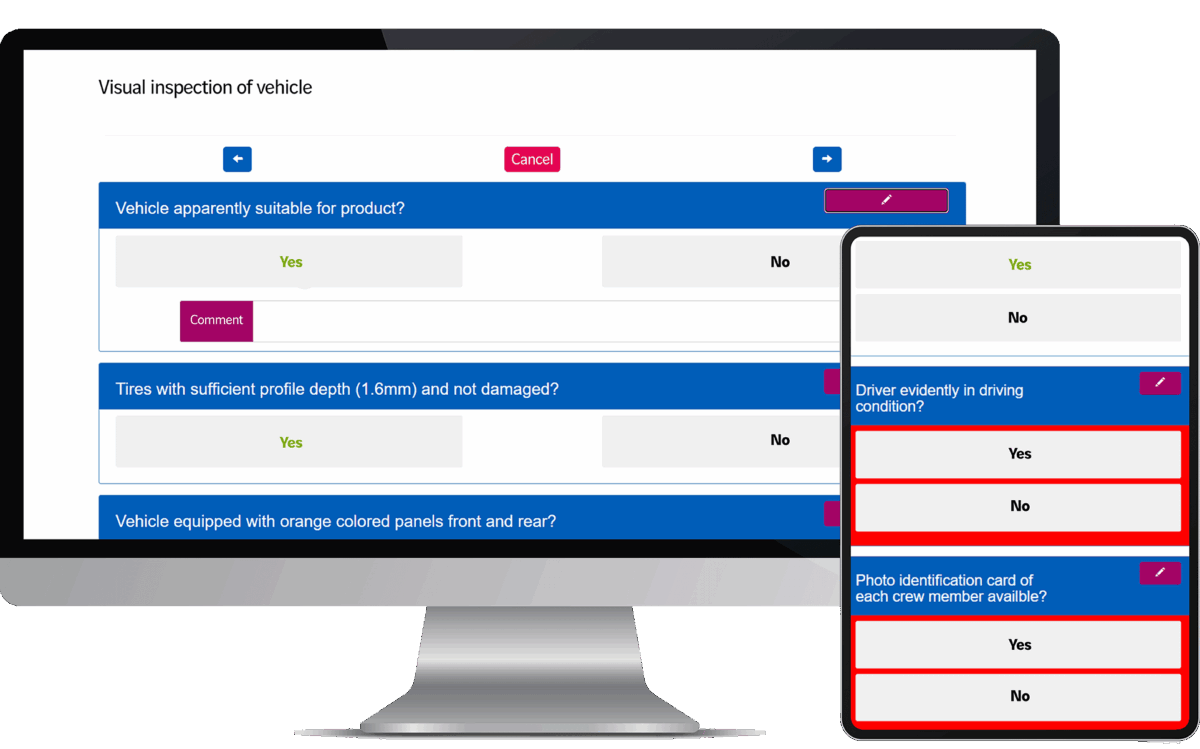

Plant Security is one of the few non-negotiable must haves for bulk material plants: Where trucks, heavy machinery and humans come into contact, drivers, visitors, service providers and plant staff must be aware of and strictly follow plant specific security regulations to avoid errors and grave accidents.

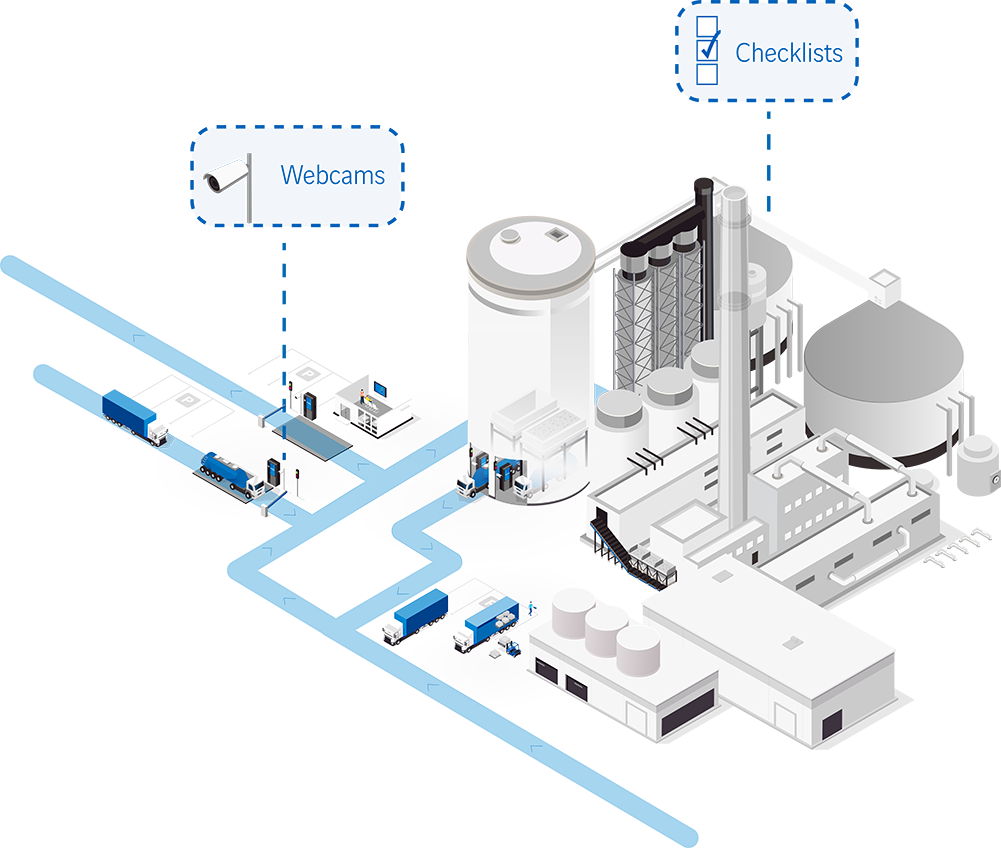

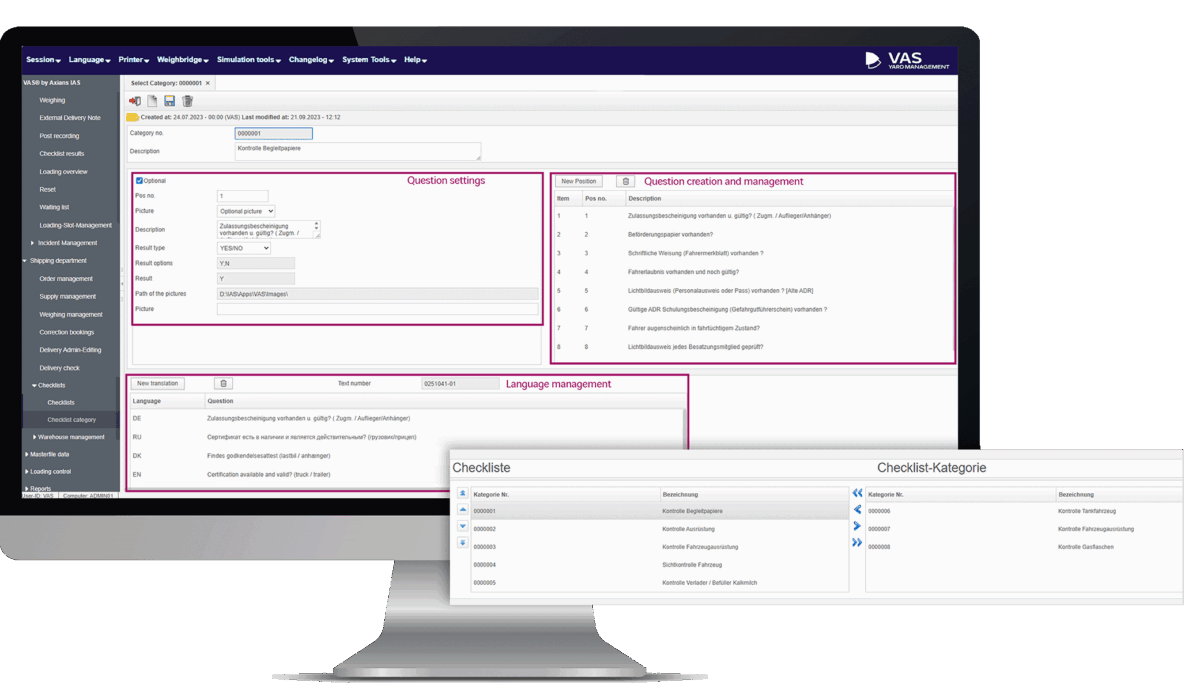

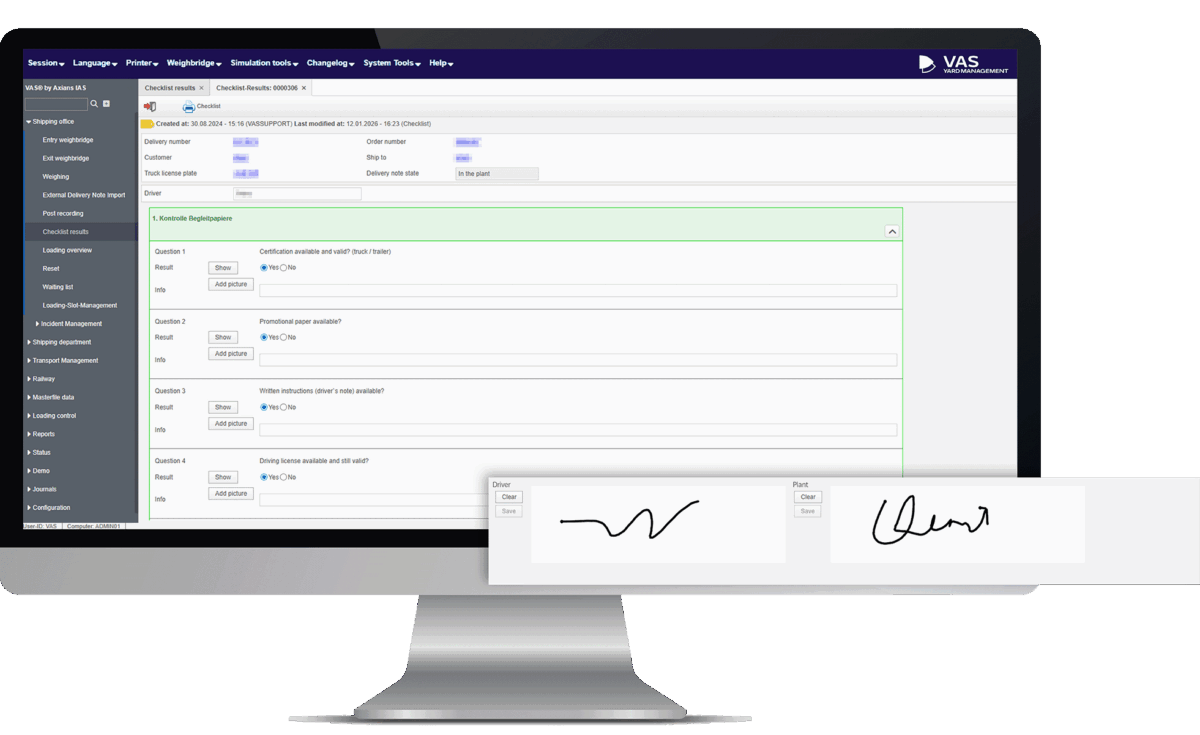

VAS offers a comprehensive set of plant security solutions that ensure secure processes from the yard entrance to the exit: