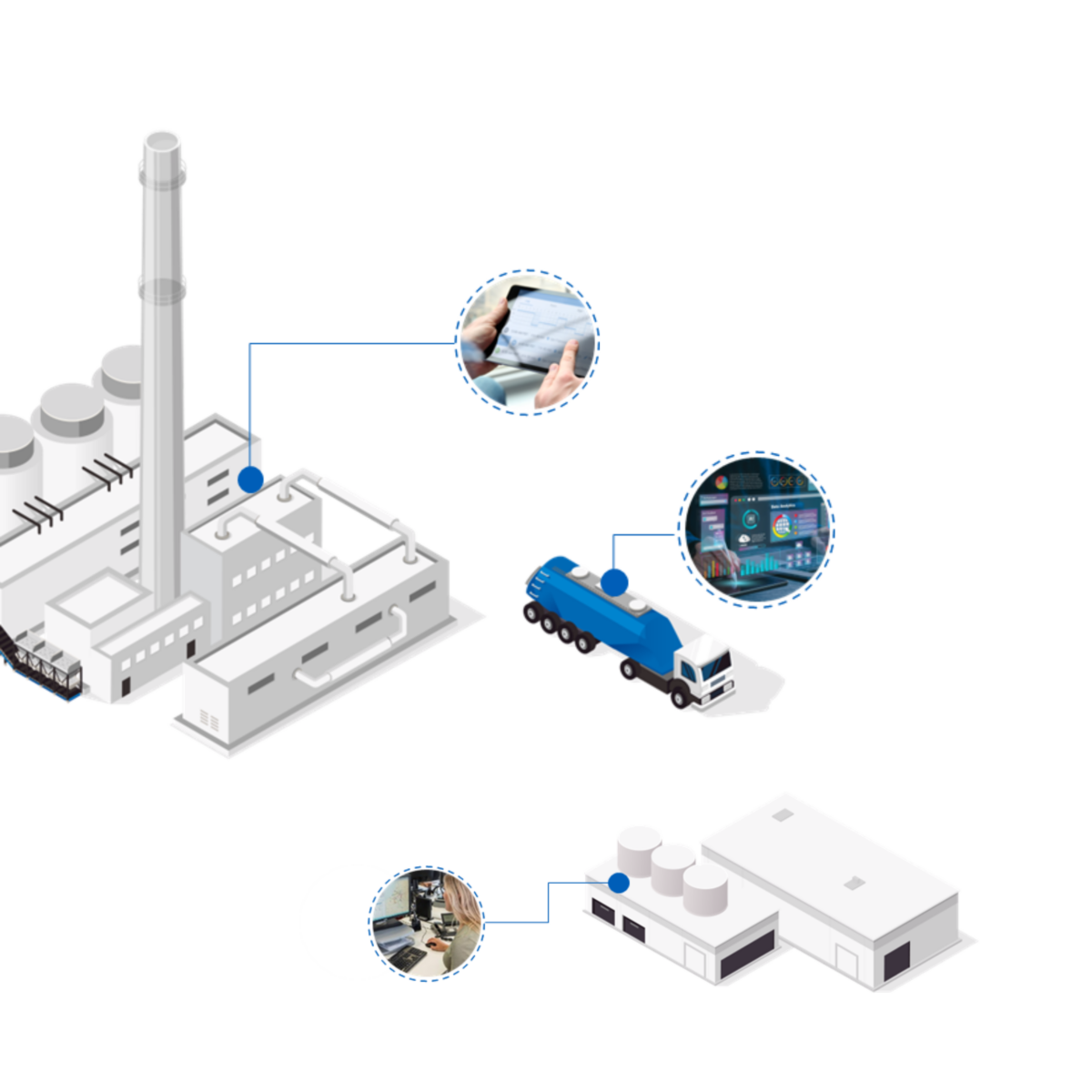

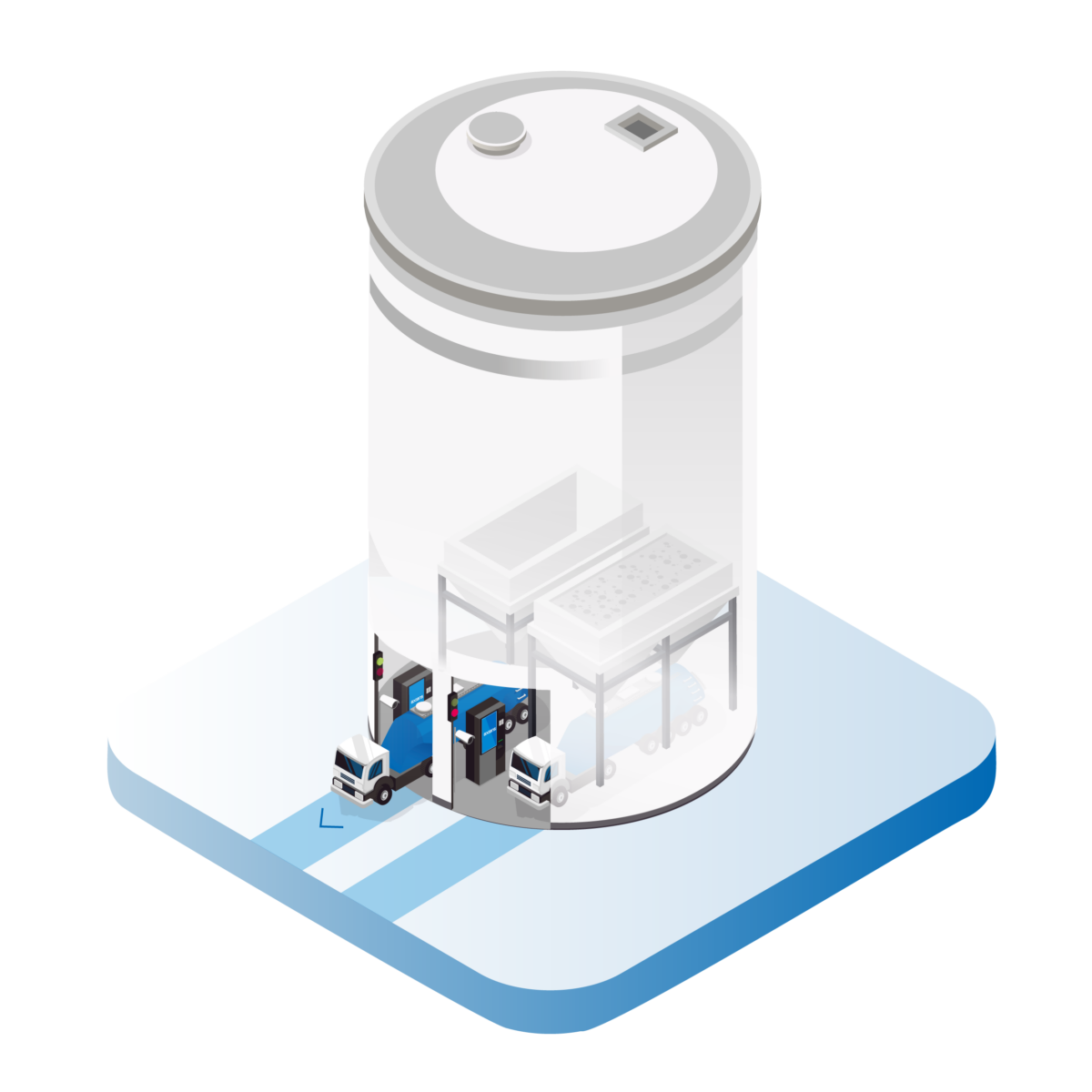

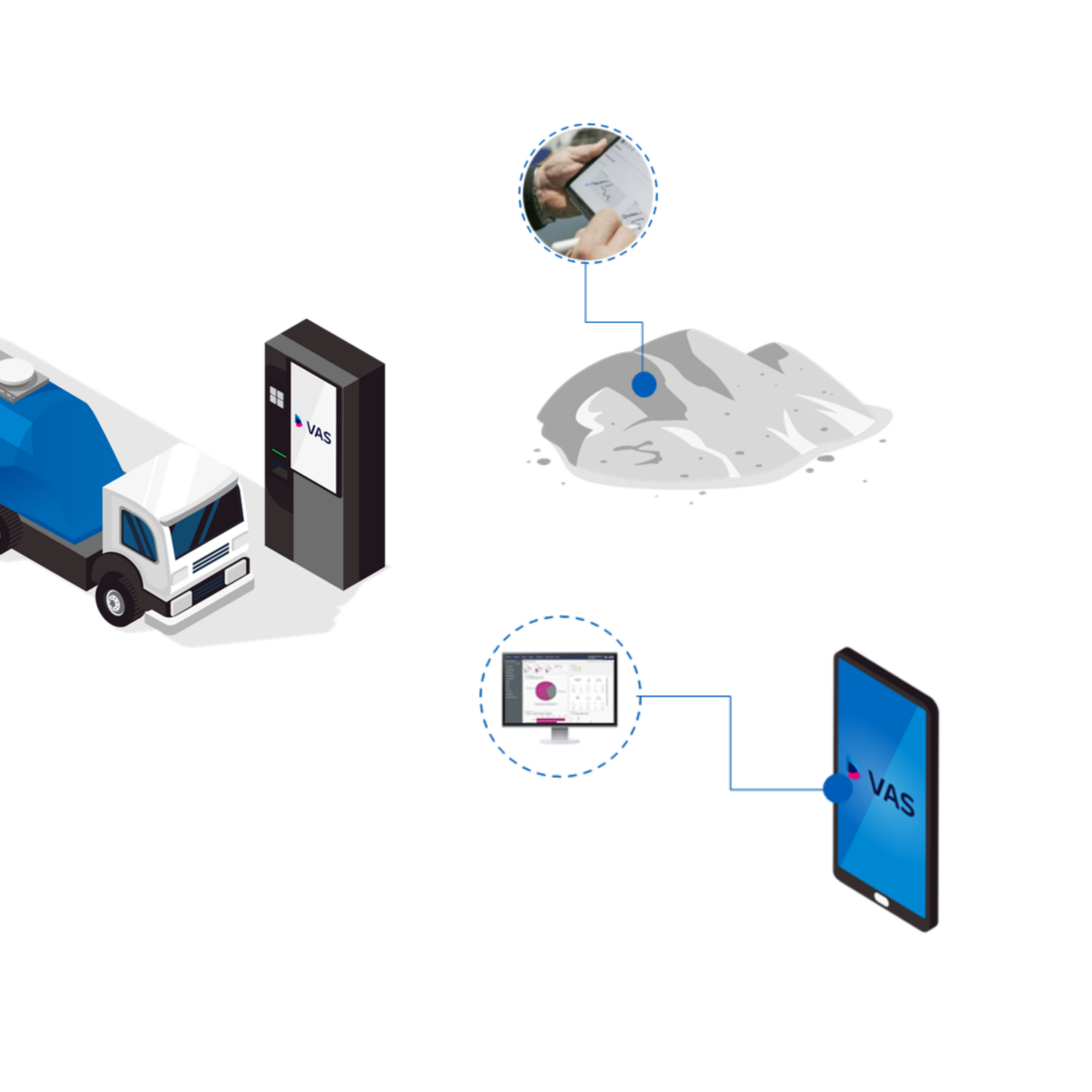

At Axians IAS, we’ve reached a major milestone: more than 1,000 industrial plants worldwide now rely on our VAS Yard Management Software to streamline their logistics operations. Our 1,000th installation was achieved in partnership with Heidelberg Materials France, marking a comprehensive rollout across 14 cement plants.

This achievement represents more than numbers—it’s proof of our unwavering commitment to simplifying and automating bulk material logistics, from truck entry to delivery processing via loading to check-out.