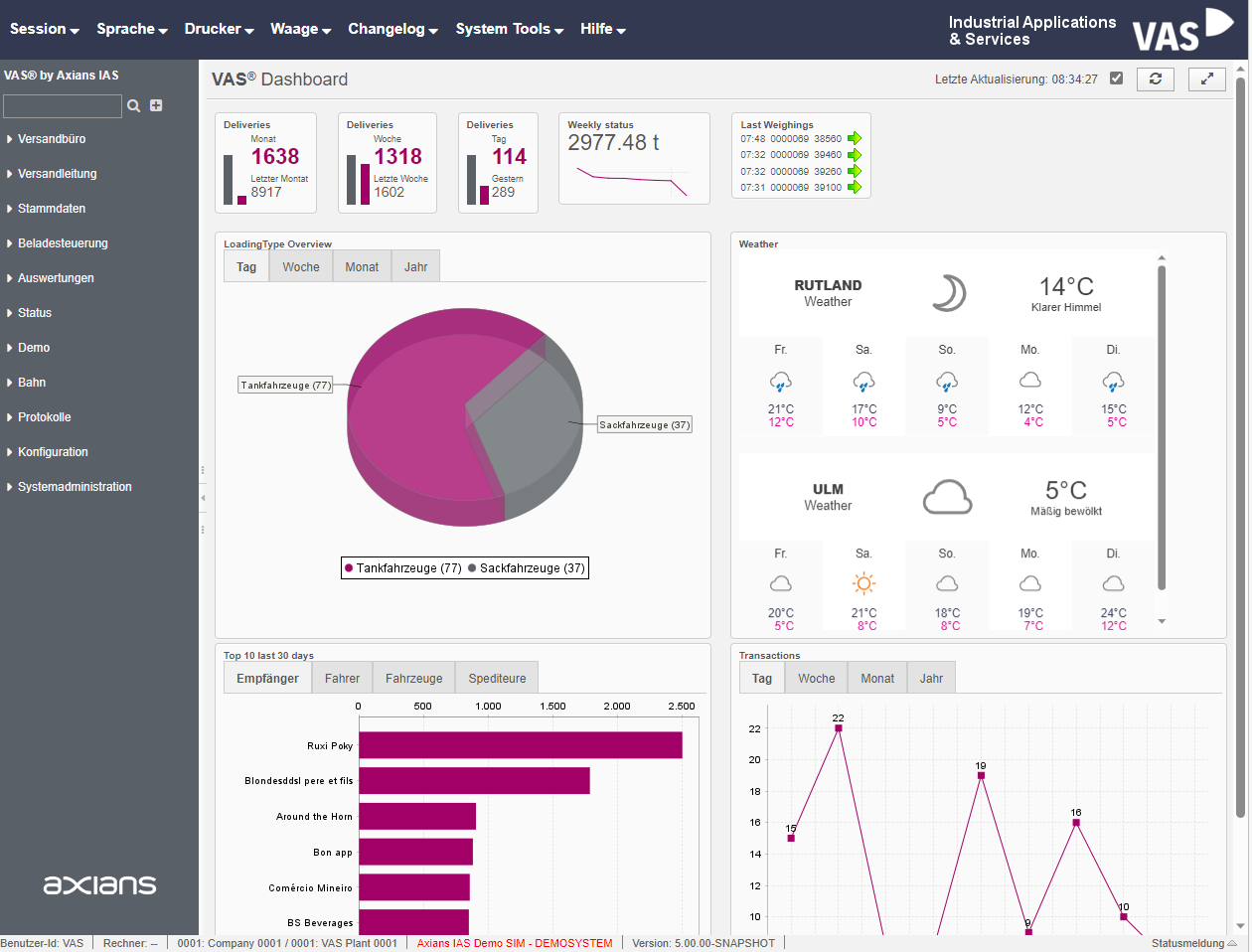

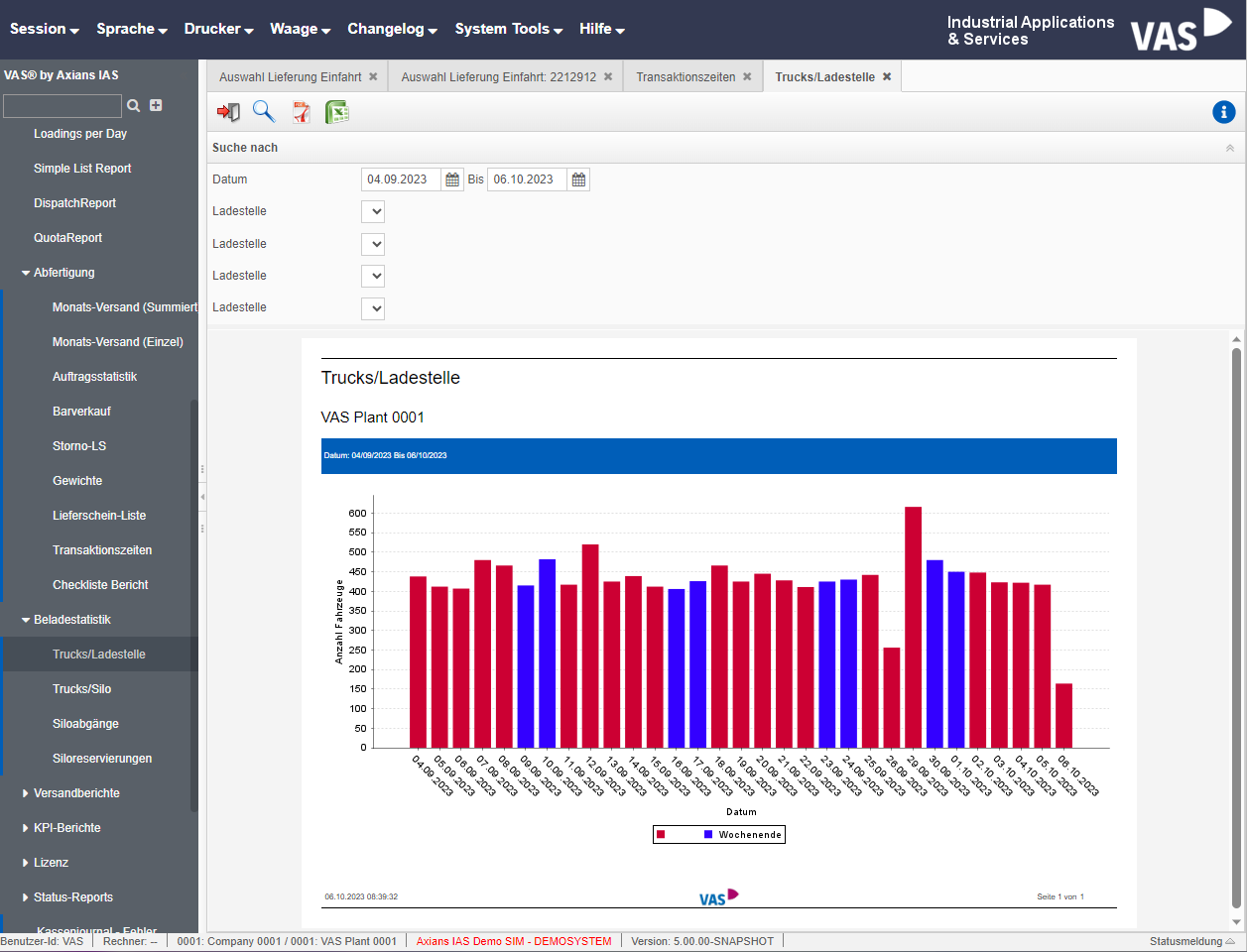

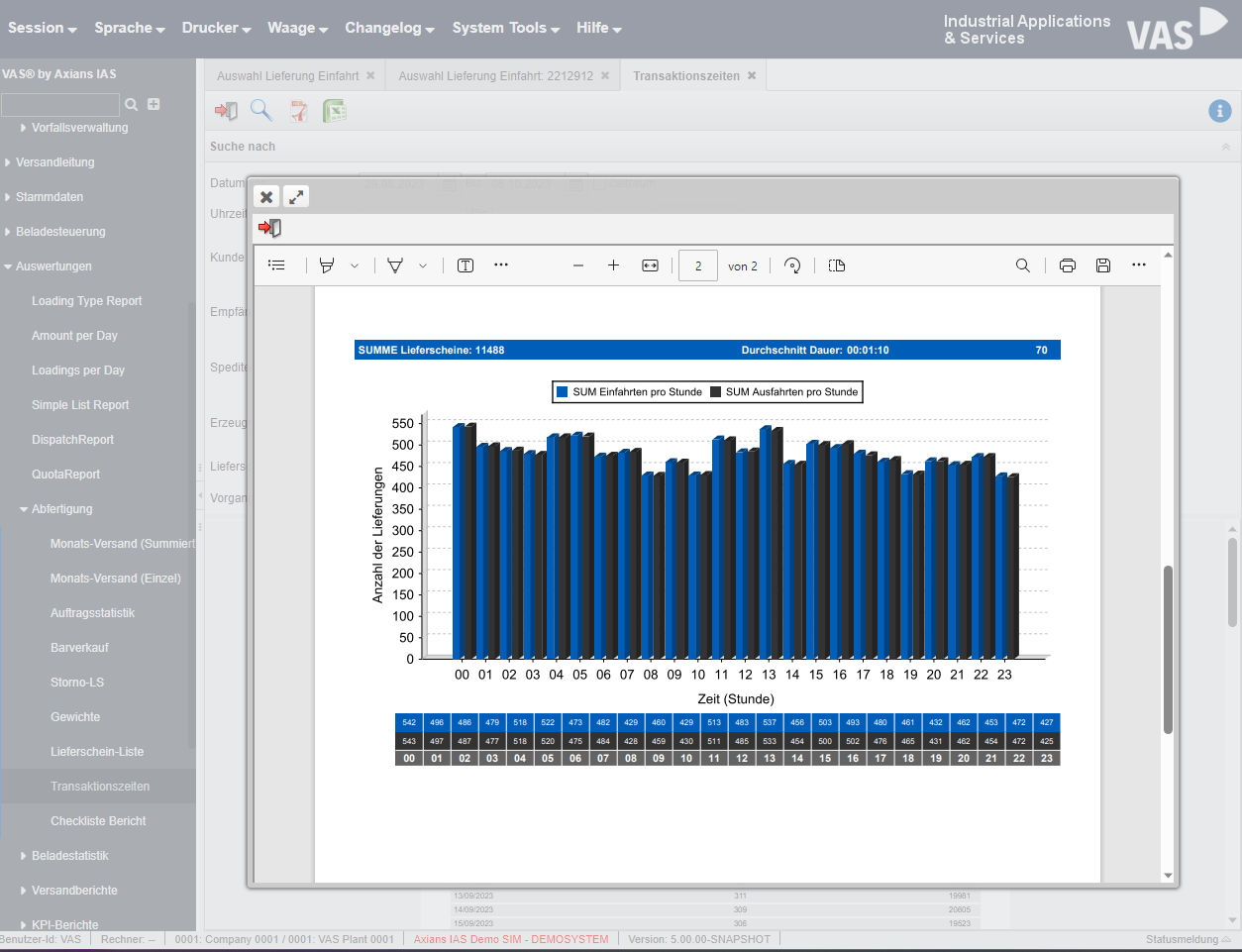

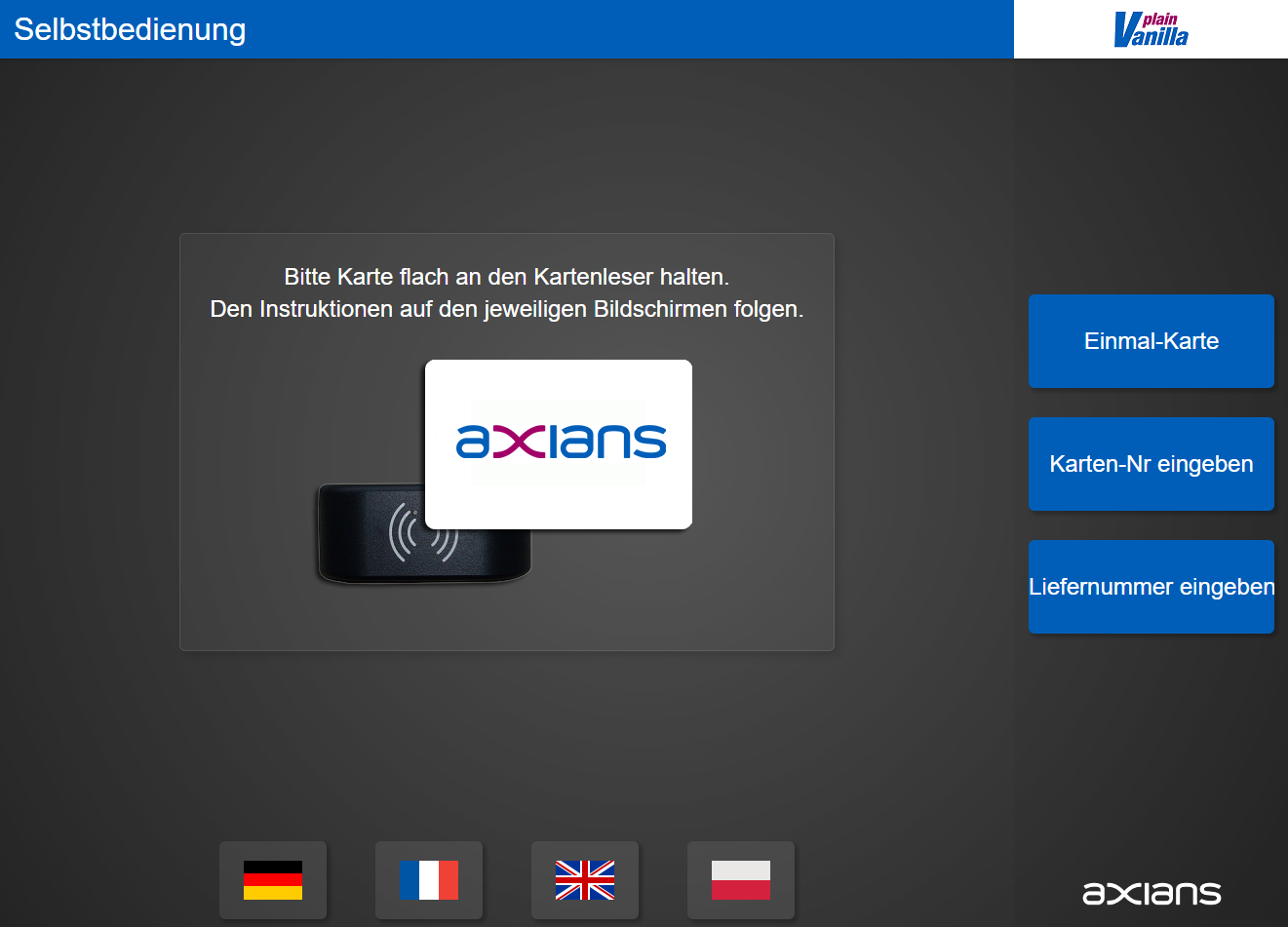

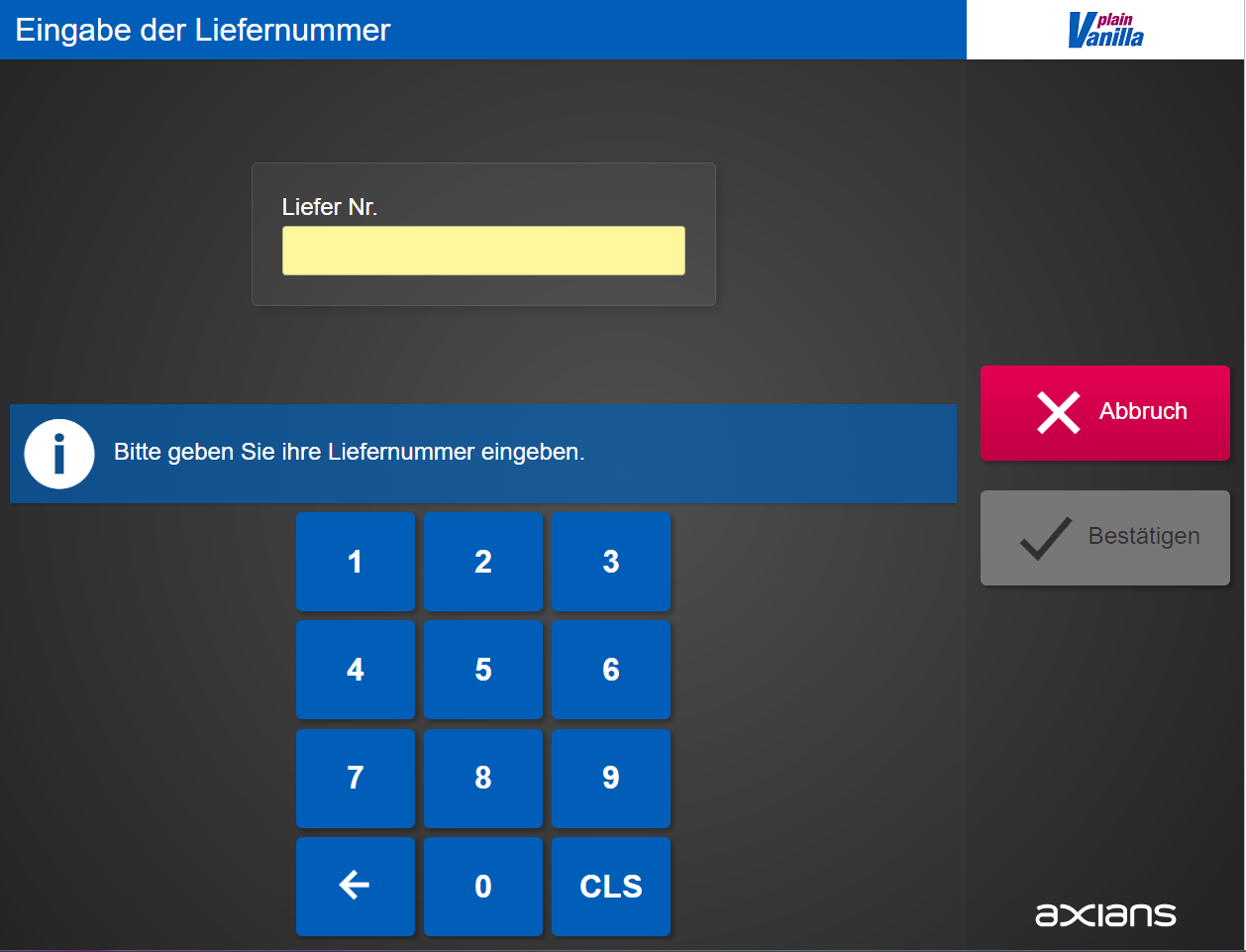

Our process-oriented VAS Yard Management Software solution VAS® for the bulk materials industry in the building materials sector for cement, sand and gravel, lime, asphalt or concrete automates and optimizes the logistics and loading processes in the plant. This enables your customers to control self-service shipping processes around the clock.

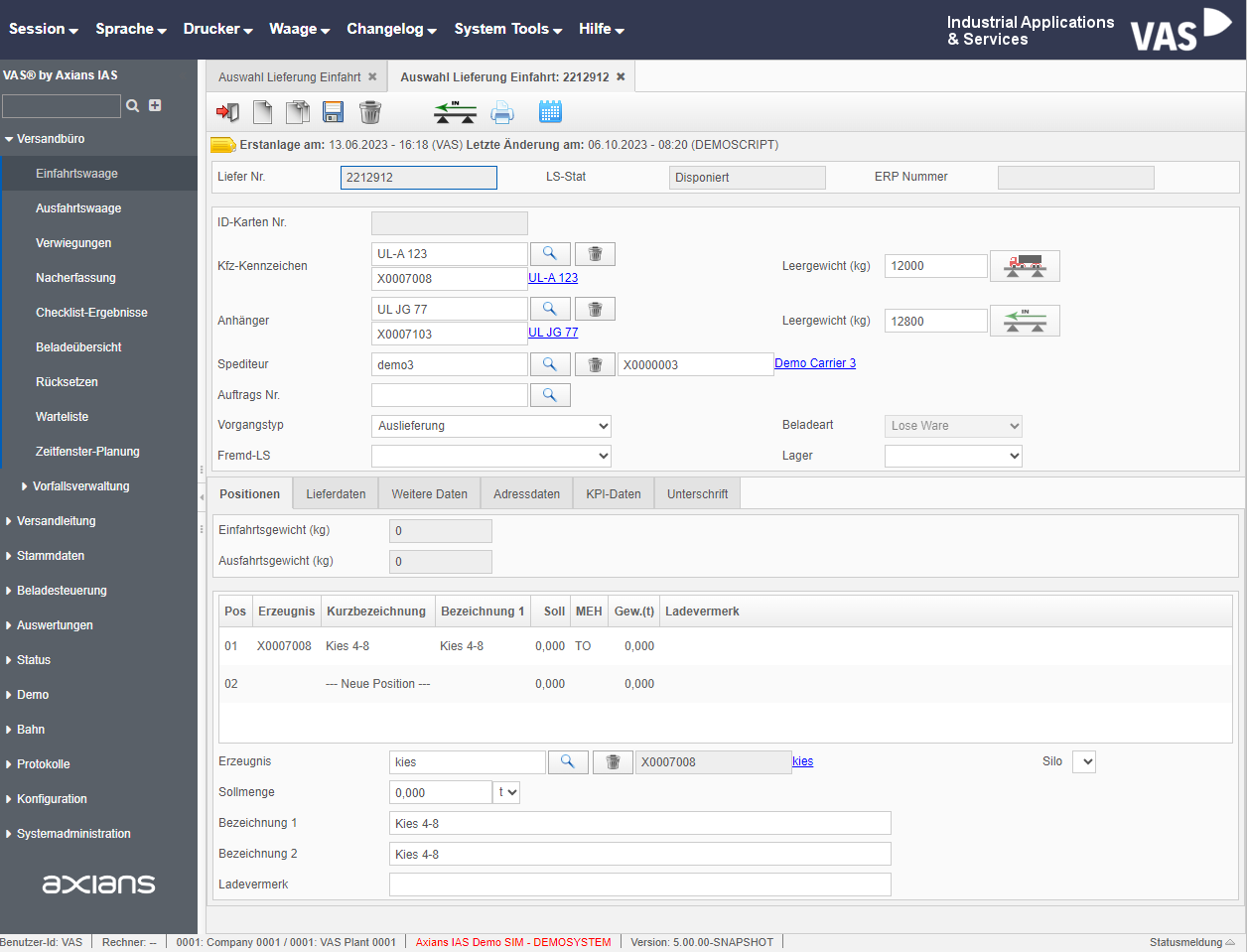

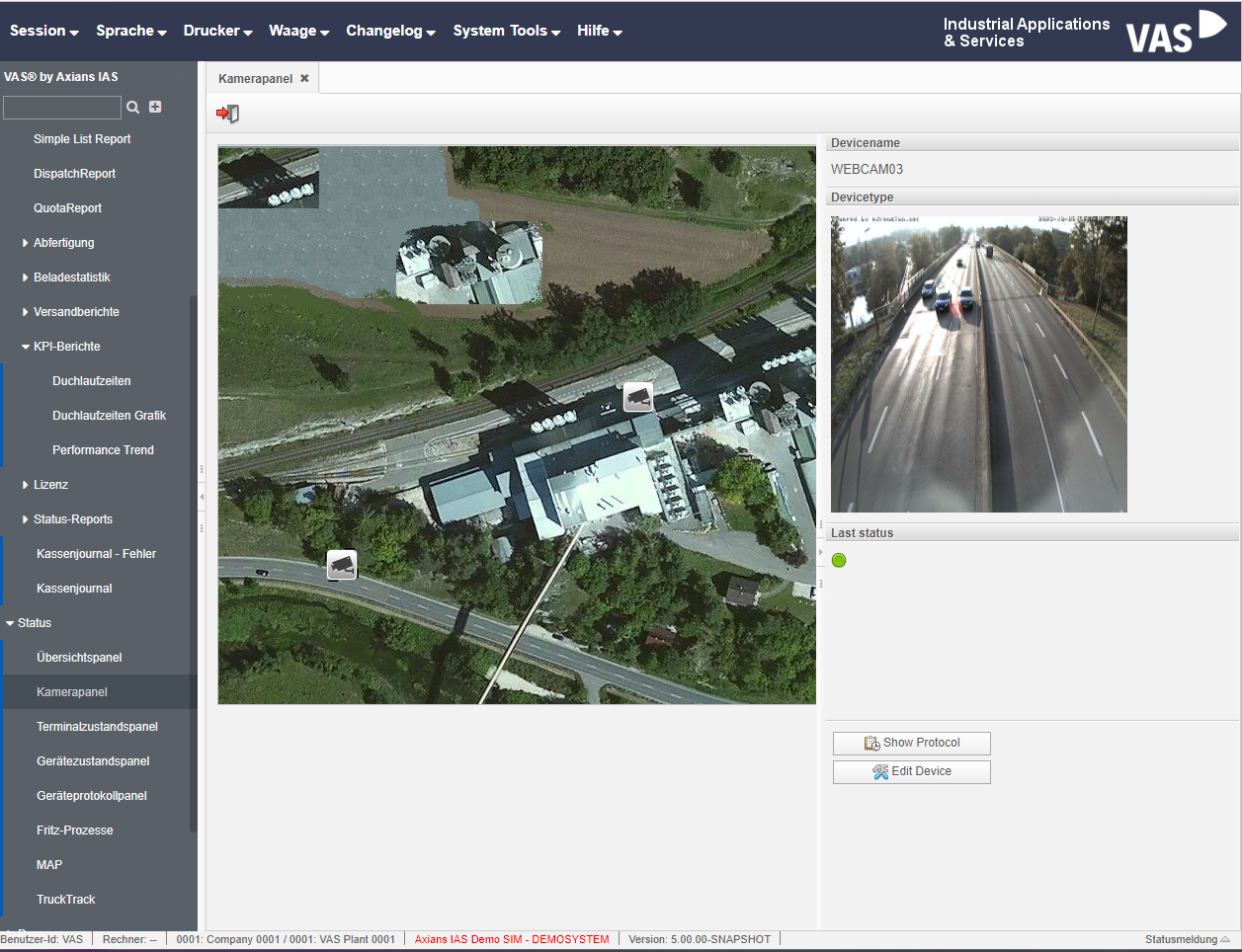

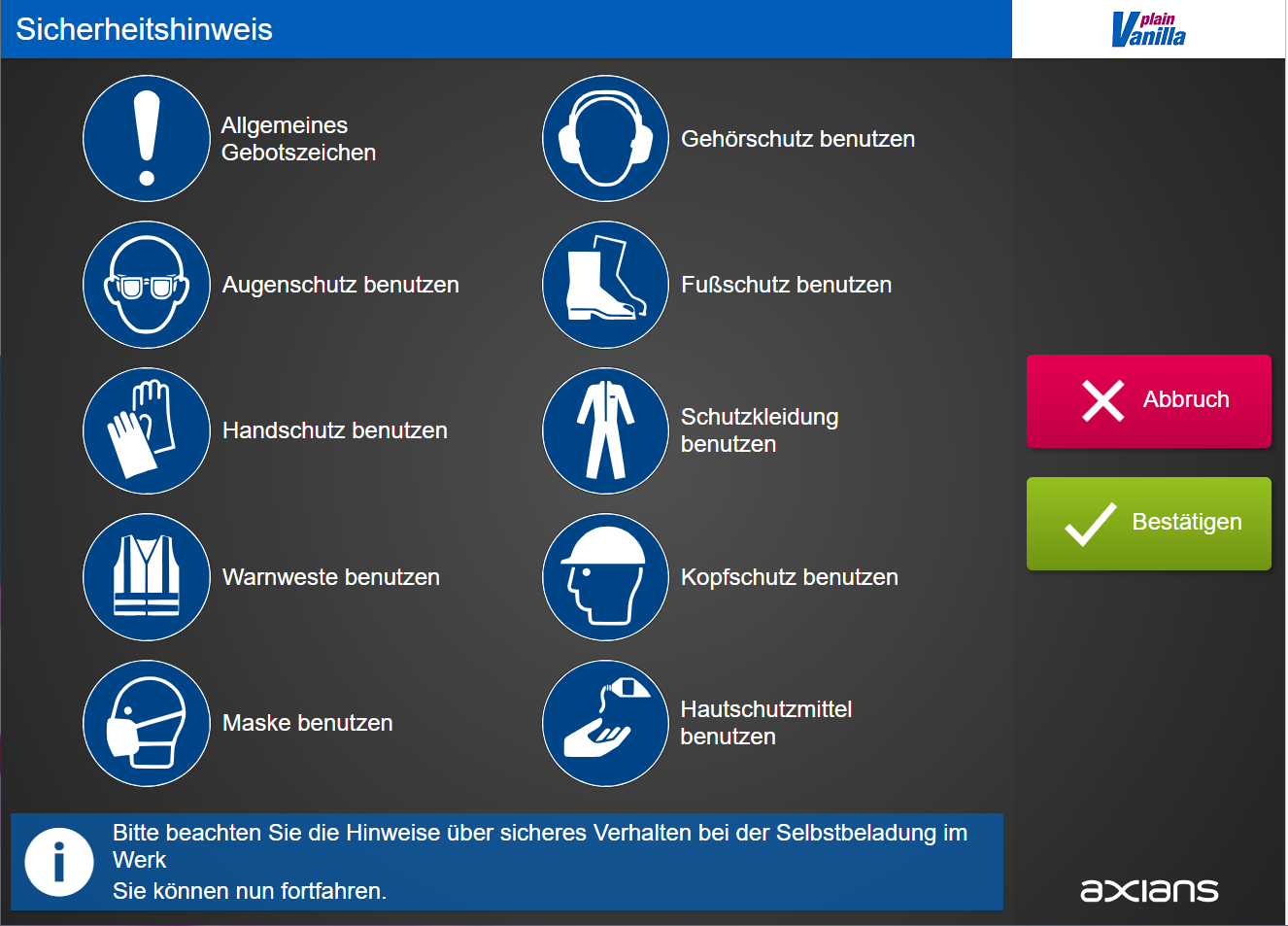

VAS Yard Management covers all vehicle handling processes within a plant. From entering the registration data for the security check at the plant entrance, followed by weighing, loading, printing of shipping documents to the controlled plant exit. VAS Yard Management is the automated, process-oriented solution for your supply chain management.

With its high scalability and customizability, VAS Yard Management is suitable for companies of different sizes and numbers of locations and supports future growth and change. As the link between your ERP and other IT systems, VAS is the key function for efficient process flows.