No more waiting times at the weighbridges, no more delays in data collection: Basalt AG, a leading supplier in the building materials industry, is transforming and standardizing its logistics processes in the natural stone division with the Germany-wide introduction of the VAS Yard Management System from Axians IAS.

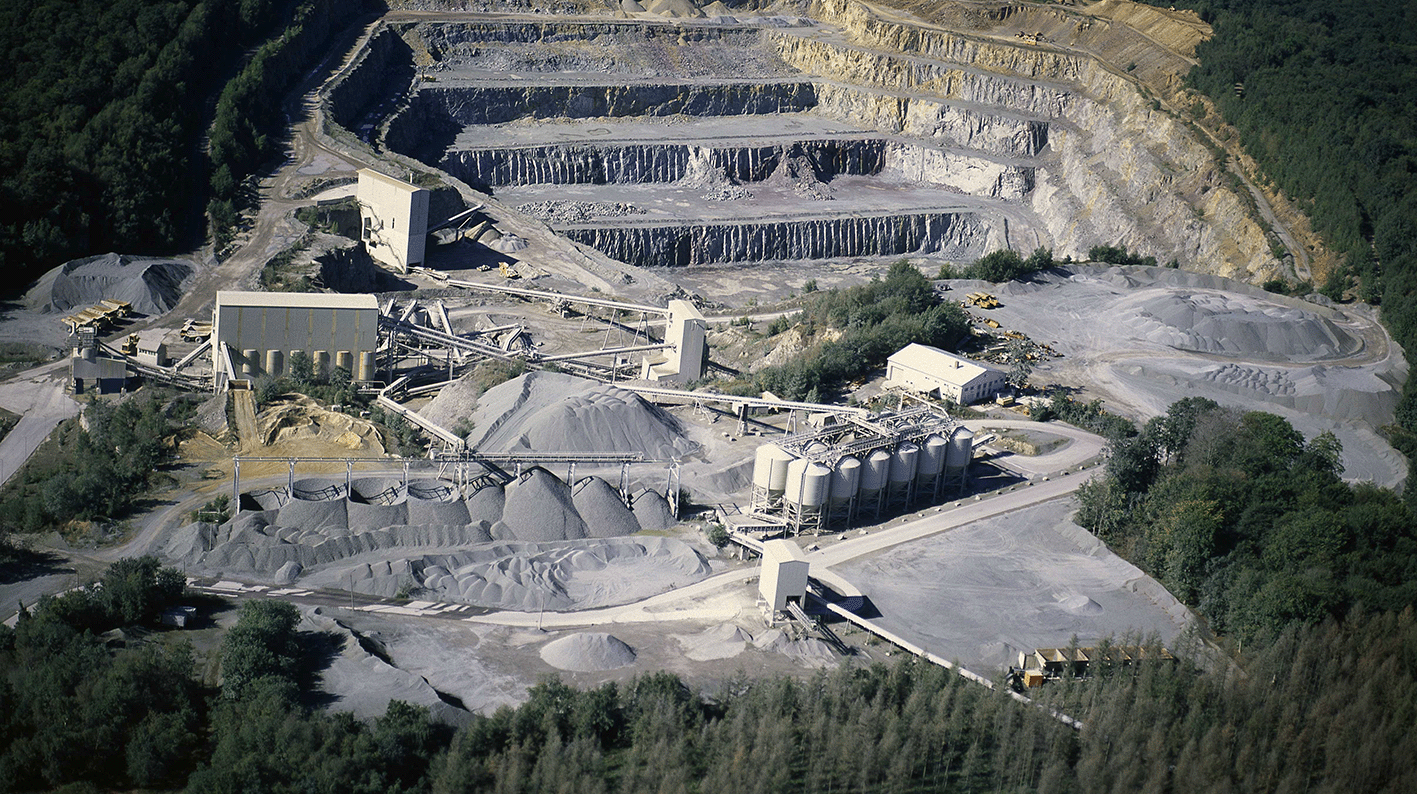

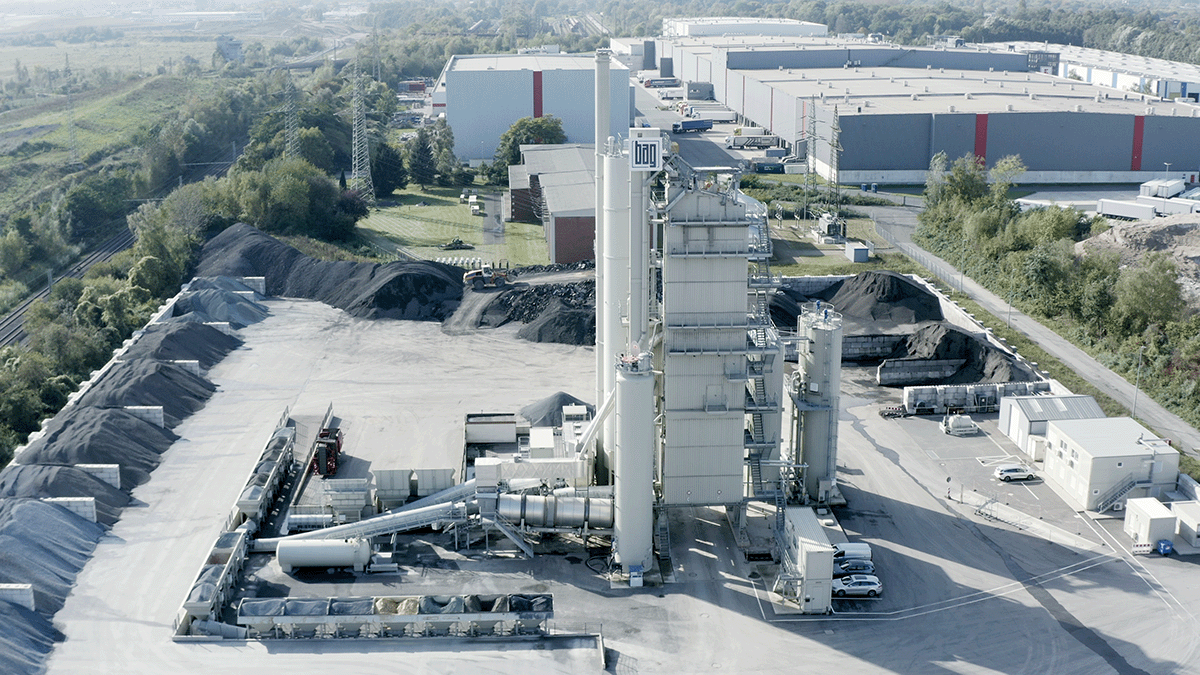

Weighing is a central component of the logistics process, as it forms the basis for invoicing, order processing and capacity planning. In the past, local automation solutions were therefore implemented around the weighbridges in the quarries, mixing plants and landfills of Basalt AG, which led to a decentralized, heterogeneous system landscape that made end-to-end interconnectedness and a synchronized data flow difficult.

A large-scale, cross-location modernization project was launched in 2017 to put plant logistics on a uniform, future-proof footing.