Author: Reiner Bachthaler

The central hub for the logistics workflow

Centralized management of logistics processes in the cement industry

In the building materials industry, too, the question arises: digitize only the processes in the factory or also take advantage of centrally controlled logistics processes? What are the applications, benefits and challenges you should know about?

In cement production, as in many other sectors of the building materials industry, the focus when automating the logistics workflow is primarily on the processes in the plant itself. Typical processes include truck check-in, check-out, the automation of loading, the integration of weighing systems and the creation of delivery bills.

However, the complexity of modern and distributed logistics processes requires a more centralized approach. This article delves deeper into the concept of a centralized logistics workflow in the building materials industry and explores the key features and considerations that building materials companies and logistics professionals should take into account to find the right solution for their use case.

5 scenarios that a local plant logistics solution does not (completely) cover

To understand the need for a centralized logistics workflow, we first look at the requirements for which a local, plant-specific solution is not sufficient:

1. easy and convenient interaction between producer and customer:

Customers have a business relationship with a supplier and not with its individual plants. Whether it is online orders, status queries or the communication of delivery information, these are always processes that are performed flexibly by different locations or roles. Local systems automatically reach their limits here.

2. delivery planning:

This point includes both the central order and loading planning by a dispatcher and the associated transportation planning by a freight forwarder. In both cases, a high degree of flexibility across locations is an absolute must. An optimized planning result with the highest process reliability and lowest costs can only be achieved with centrally controlled planning.

3. delivery processes:

Managing and tracking deliveries after they leave the factory is most effective when it is centralized. Mixing plants or construction sites often receive materials from different plants, which underlines the need for a centrally controlled delivery process.

4. data consistency and transparency:

Providing consistent data just in time across the entire logistics chain for all roles and plants involved is a requirement that local systems usually fail to meet. A centralized logistics solution brings the greatest benefits here, especially if it is perfectly integrated with local plant logistics solutions such as Axians VAS Yard Management.

5. flexible access options:

Various users, including employees from different plants, the supplier’s head office, purchasers, freight forwarders and recipients, must have flexible and convenient access to the required data – an almost impossible task for local, plant-specific solutions.

Key areas for a centralized logistics workflow

We have seen where local solutions reach their limits. The most important use cases for a centralized logistics workflow can be derived from this. Here is an overview, which can of course be supplemented by other areas:

Material buyers benefit from more flexibility, transparency and less effort when creating orders. A central ordering system that is available online at all times, independent of the individual production plant, is therefore essential for convenient and smooth order entry and management.

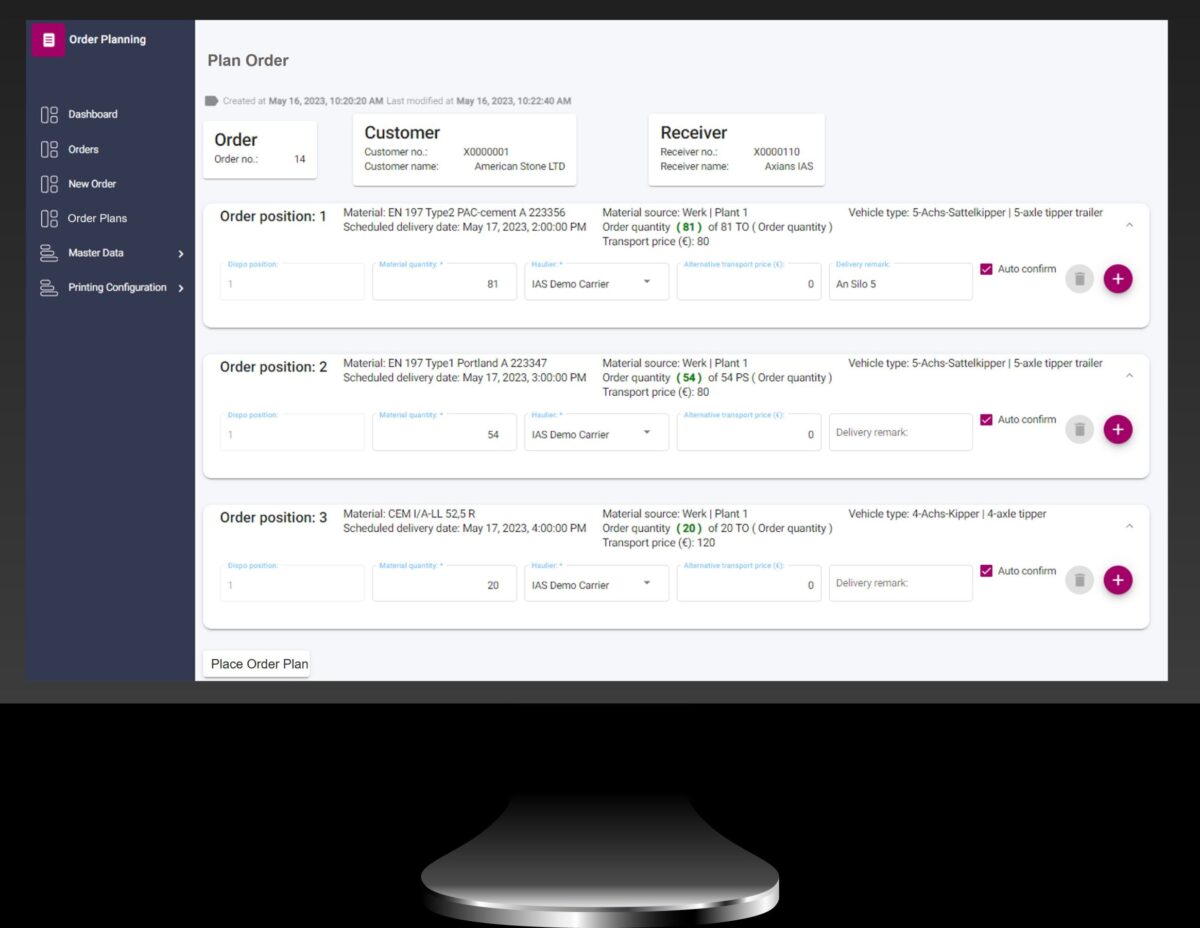

A central order planning system should enable the efficient processing of cross-plant scheduling tasks. This includes cross-plant planning and confirmation (or rejection) of orders, changes to the material source and assignment of carriers to transport orders.

The main tasks for scheduling here are the detailed planning and optimization of transport orders, including Assignment to vehicles and drivers, as well as communication with the client (confirmation of freight orders, status updates, etc.). This could be an integrated component of a central workflow solution for the entire logistics process, or could also be realized through the online connection of a separate, AI-based transport optimizer.

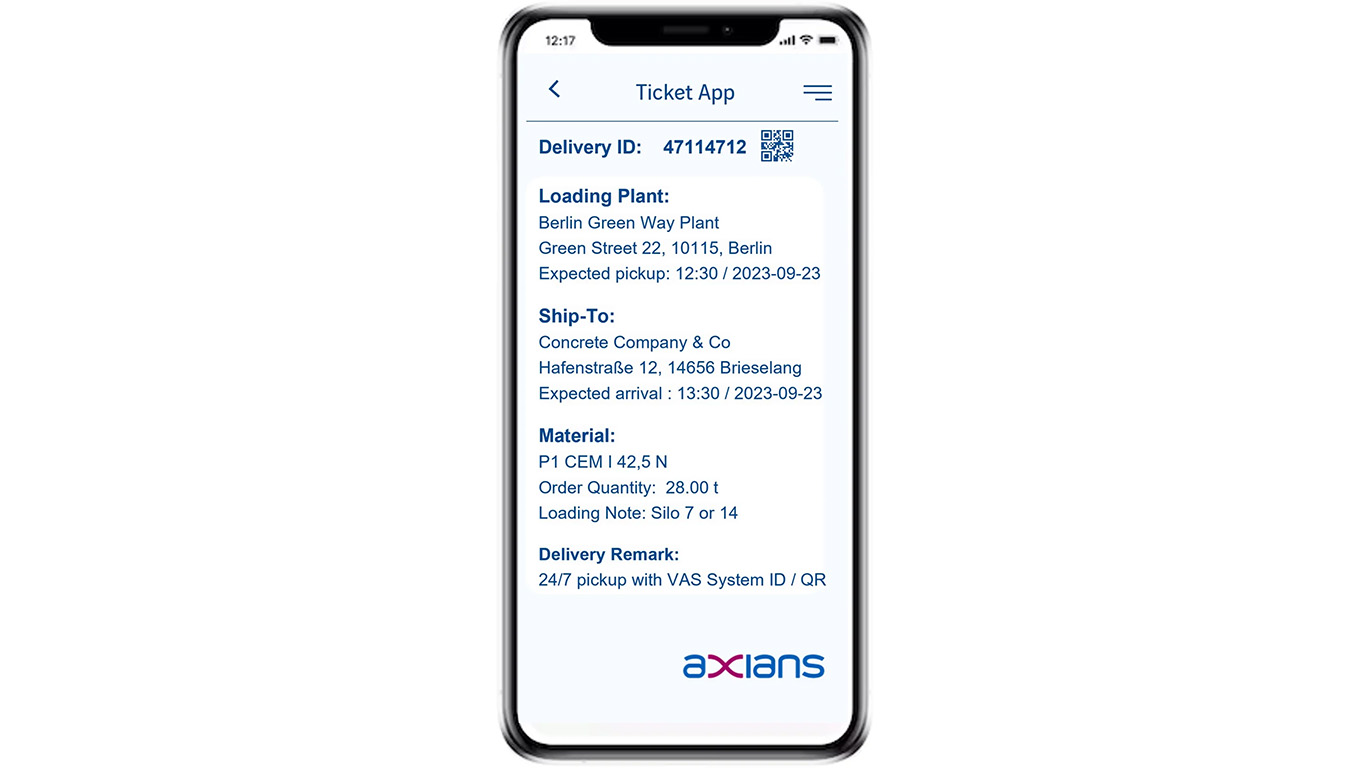

Central storage and retrievability of delivery data not only simplifies data management, but also reduces manual intervention and document printouts. Solutions such as the Axians Ticket App enable convenient automated access to delivery data for various users – simply by scanning a QR code or an automated upload.

Central storage and retrievability of delivery data not only simplifies data management, but also reduces manual intervention and document printouts. Solutions such as the Axians Ticket App enable convenient automated access to delivery data for various users – simply by scanning a QR code or an automated upload.

Analyses and statistics provide valuable insights into the efficiency of logistics processes. This offers a wide range of applications, from current planning overviews of deliveries due in the short term to long-term performance analyses (e.g. proportion of rescheduling and delays).

A desktop solution makes no sense for truck drivers or a site manager, for example. You need a smartphone app that is perfectly connected to a central workflow solution and displays the logistics data for different roles in a targeted manner.

What you can achieve with central logistics workflow solutions

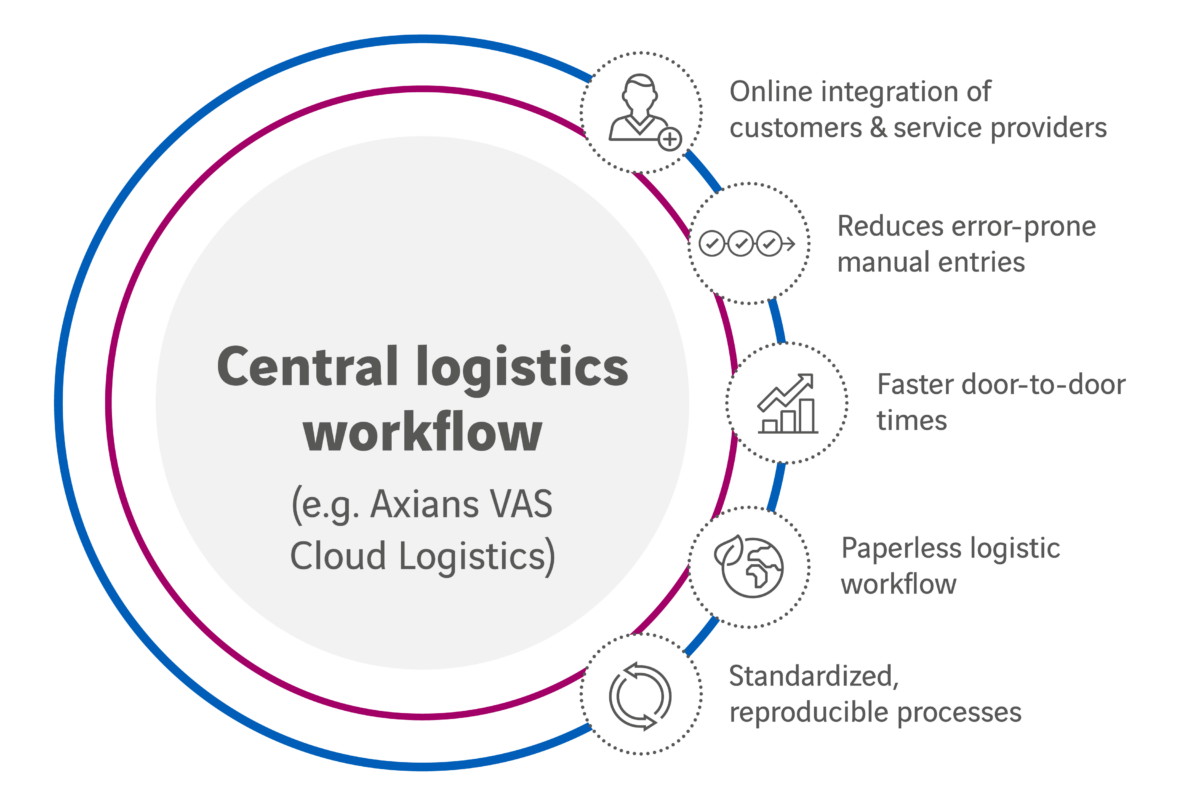

We now know the most important areas of a centralized logistics workflow. But what are the advantages of using them? Here is a brief overview of the benefits that can be realized with the modular and scalable VAS Cloud Logistics solution from Axians IAS:

Key challenges that need to be overcome

We see the considerable advantages of a centralized logistics workflow, but of course there are also challenges. Implementation may sound like a difficult and time-consuming large-scale project, but it doesn’t have to be. The key lies in a scalable and modular solution approach. This makes the effort and costs manageable and the implementation project can be individually adapted to the respective needs and resources.

Integration with existing systems such as ERP and yard management is also a key success factor. These integration projects must be carefully planned with precise knowledge of the process flows and the data to be exchanged.

Another challenge is change management: employees must adapt to new processes and systems and the transition must be effective and with minimal disruption to operations.

Protection also plays a key role in centralized data storage: strong security measures and consistent compliance with data protection regulations are therefore essential, especially for cloud-based solutions, and this is one of the core competencies of the major hyperscalers.

Introduction with a professional partner

Implementing a digitalization project in the building materials industry can be quite complex, especially with limited staff that is often competing with many other ongoing projects, such as the switch to S4/HANA. This requires the expertise and strength of a solution provider and not just a pure software supplier.

The Axians IAS team can bring your logistics processes up to date, automate them and support you with the best steps. Both the introduction of standard software and customized solutions are part of our portfolio, with which more than 10,000,000 deliveries per year in the building materials industry are processed in an optimized manner.

Conclusion

The introduction of a centralized logistics workflow is not the super-complex project that it might appear to be at first glance. Modern, cloud-based solutions such as VAS Cloud Logistics from Axians IAS offer a modular and scalable solution approach. They ensure centralized data storage and management, offer all parties involved a high level of automation with consistent data and maximum transparency. This approach is particularly important for building material producers with many plants who want to improve their process automation and significantly increase the efficiency of their logistics processes.